All coils produced by us meet the relevant electrical standards, such as IEC 60034, BS EN 50209 and IEEE 1553 & 1043 and our in-house testing facility offers the following routine testing procedures:

- Surge comparison or turn to turn test (2 UN) + 1000

- Tan δ / Tip Up

- Hi-pot (AC and DC flash) test (2 UN + 1000)1.2

- Lamination test

- Partial Discharge test

- VE test

We can also test to customer specifications as required.

Voltage Endurance Testing

VE is a test that quantitatively measures the capability of an insulation system to withstand partial discharge (corona) at operating temperature, which in turn is a measure of the quality of the design of the materials, and of the manufacturing process.

High voltage stress causes aging of stator winding insulation and eventually leads to insulation failures. This, widely accepted, accelerated life cycle test is used as a measure of quality by applying a much higher than normal machine-operation stress to coils/bars within a short period of time to accelerate insulation aging which occurs during machine service.

This means customers can be assured that coils are manufactured to maximise the lifetime performance of the coils and reduce any potential partial discharge which could cause premature failure.

Partial Discharge testing

We also carry out Partial Discharge testing on our coils.

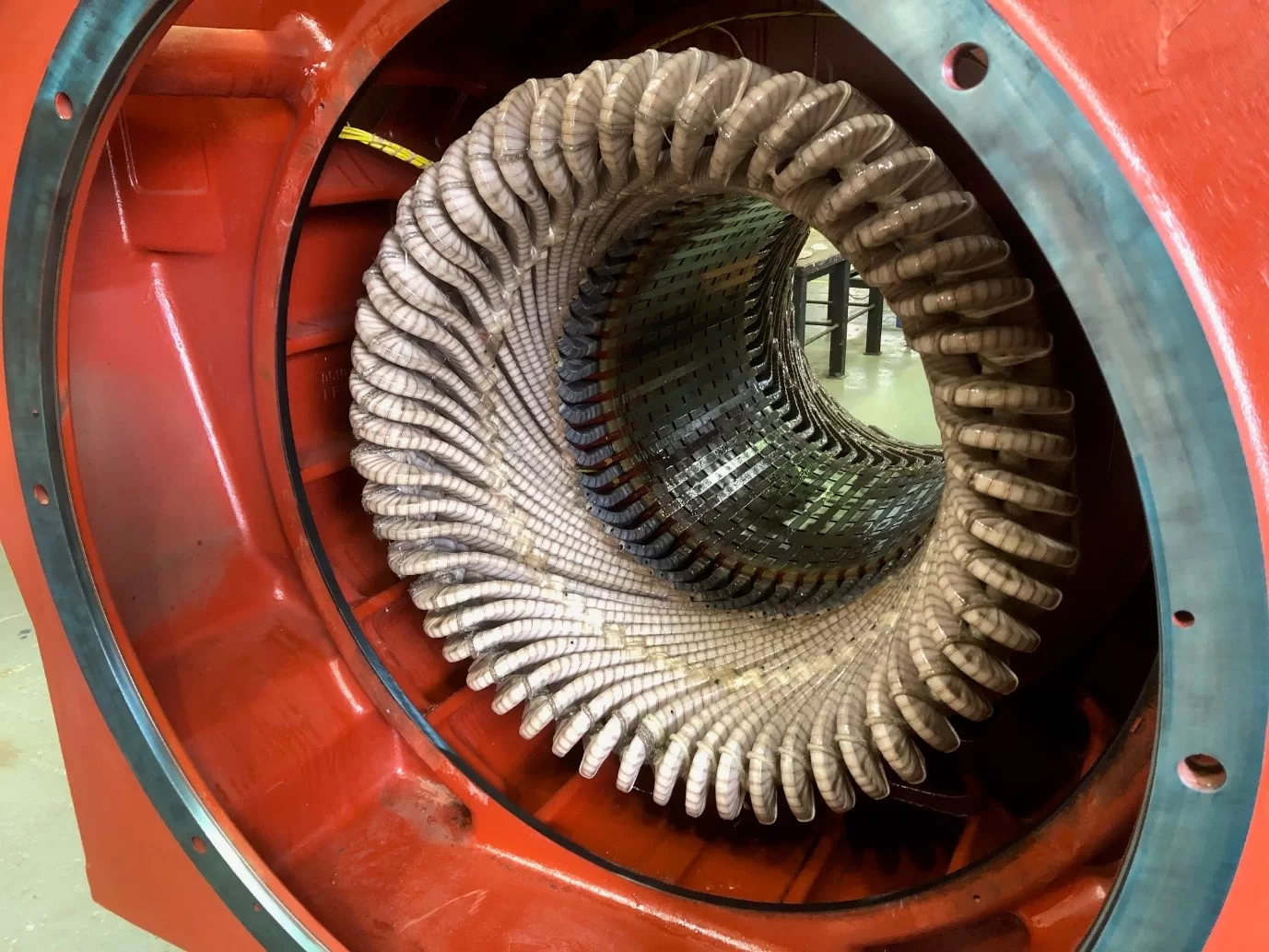

Corona discharge activity at the exit of the core is designed out by using the highest grade of corona stress grading tapes applied using a proven process and the corona discharge activity at the slot portion is overcome by using hot pressed corona protection tape which provides a resilient continuous corona protection shield.

We control the PD to less than 300 pC (picocoulombs), this gives both ourselves and our customers the confidence that a much longer life expectancy can be achieved and the security that any PD emanating from the coils in the wound motors and generators can be minimised.

If required, we can PD test each coil as it is manufactured which gives increased confidence in the quality of the coils and their ability to maximise the life of the asset once rewound.

Independent Testing

HiFLEX™ coils were subjected to the following tests by a leading independent Canadian testing laboratory, with satisfactory results:

- Visual inspection and tap tests on the coils before and after VE test

- Partial discharge (PD) analysis at 7.3kV before the VE tests, as per IEEE Standard 1434-2000

- Dissipation factor (DF) measurements as per IEEE Standard 286-2000 from 2kV to 16kV in 2kV steps before the VE test

- Turn to turn insulation test before VE test as per IEEE Standard 522-2004

- Voltage Endurance Test as per IEEE Standard 1043-1996 at 31.7kV, 90°C for 500 hours

- Dissection and microscopic examination of coil after VE test

- Insulation thickness measurements of one coil after VE test

Independent Testing Results

Turn Insulation Test complied to:

- As per IEEE Standard 522-2004

- 5 successive voltages were applied to the coils with both polarities before the VE test

Voltage Endurance Test

- Coils were satisfactorily subjected to an accelerated insulation-ageing program

- As per IEEE Standard 1043-1996 and IEEE Standard 1553-2002

- Test parameters were 31.7kV at 90°C for 500 hours

- Both coils passed the 250 hours required by IEEE 1553

- Coil 1 passed by 161% and coil 2 passed by 182%

Further Information

Related Services

Related Case Studies

Leppert Nutmeg

Reads Electric Company

Contact us for more about our High Voltage Coil Testing & Diagnosis services

Get in touch using the boxes below and we’ll get back to you.