The challenge

Reads Electric Company electric motor repairers and service provider based in Western Australia, experienced an historic problem with partial discharge in a motor. Reads Electric approached Houghton International for advice on how best to eliminate this problem.

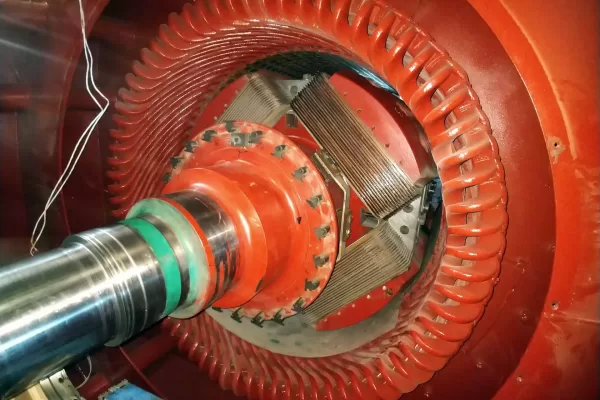

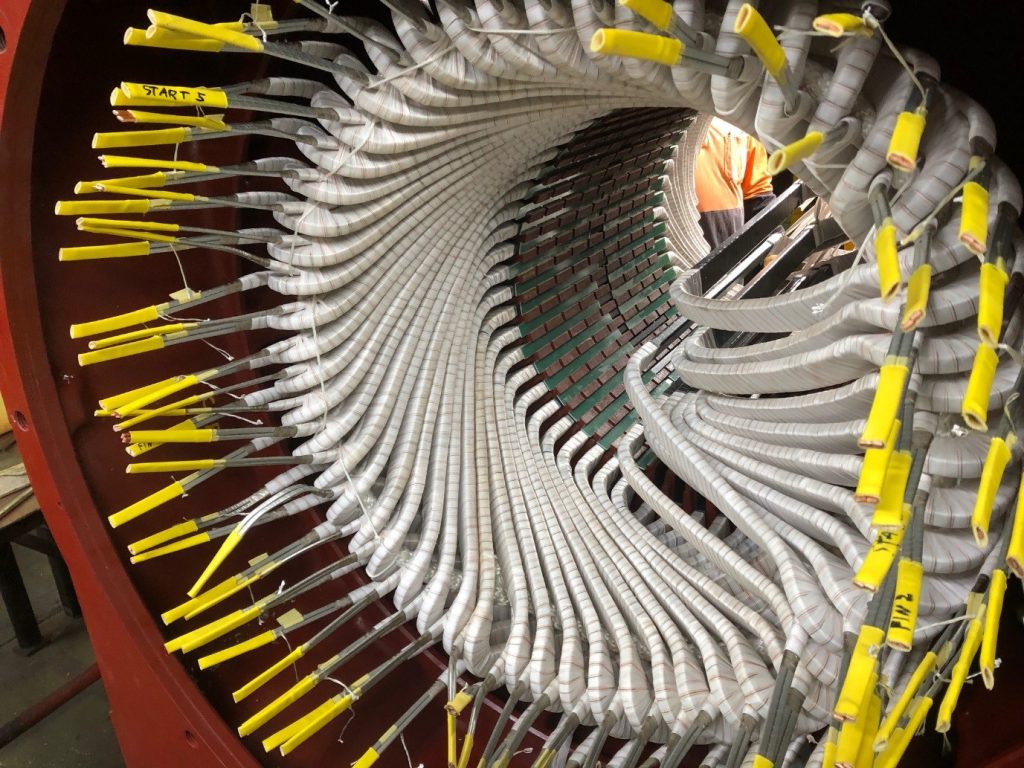

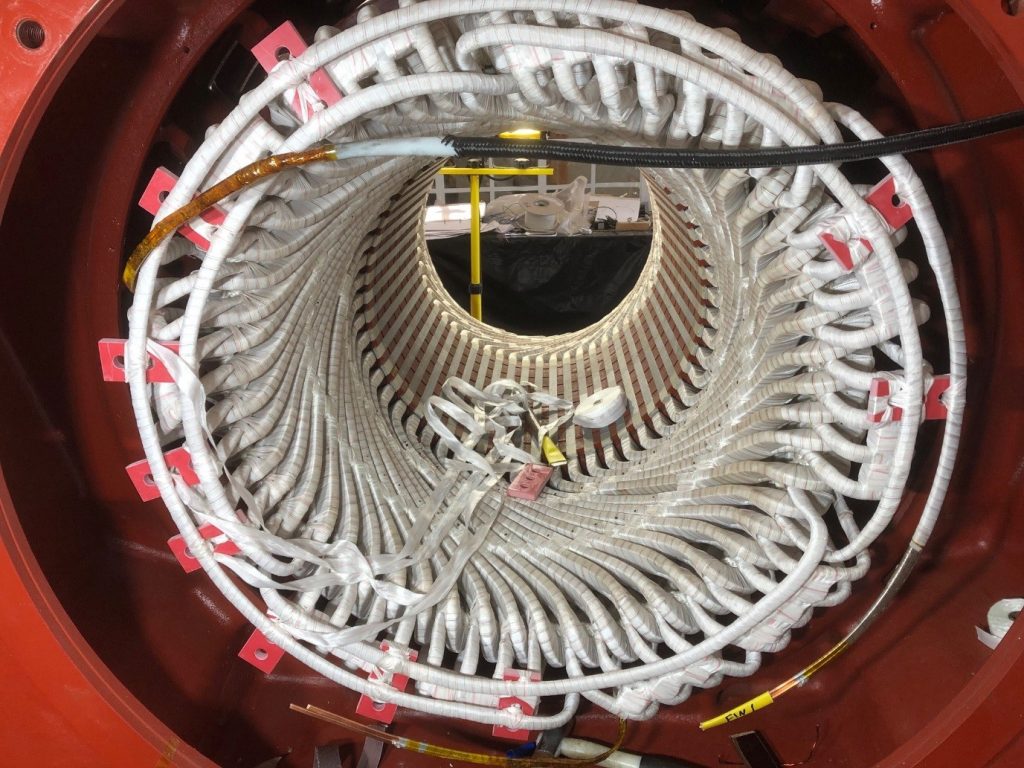

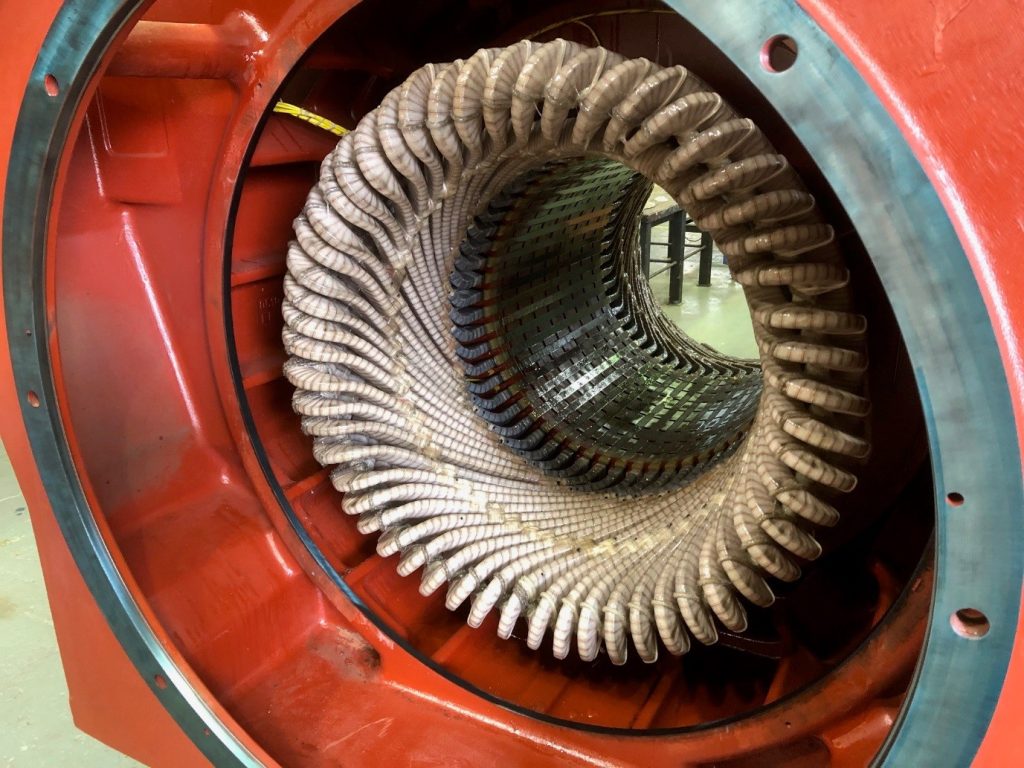

Subsequently, Reads Electric placed an order with Houghton International to manufacture and supply 54 (+2 spare) high voltage stator coils. The coils were for a 11kV, 2,600kW, 2-pole motor operating at a utility company in Australia.

The solution

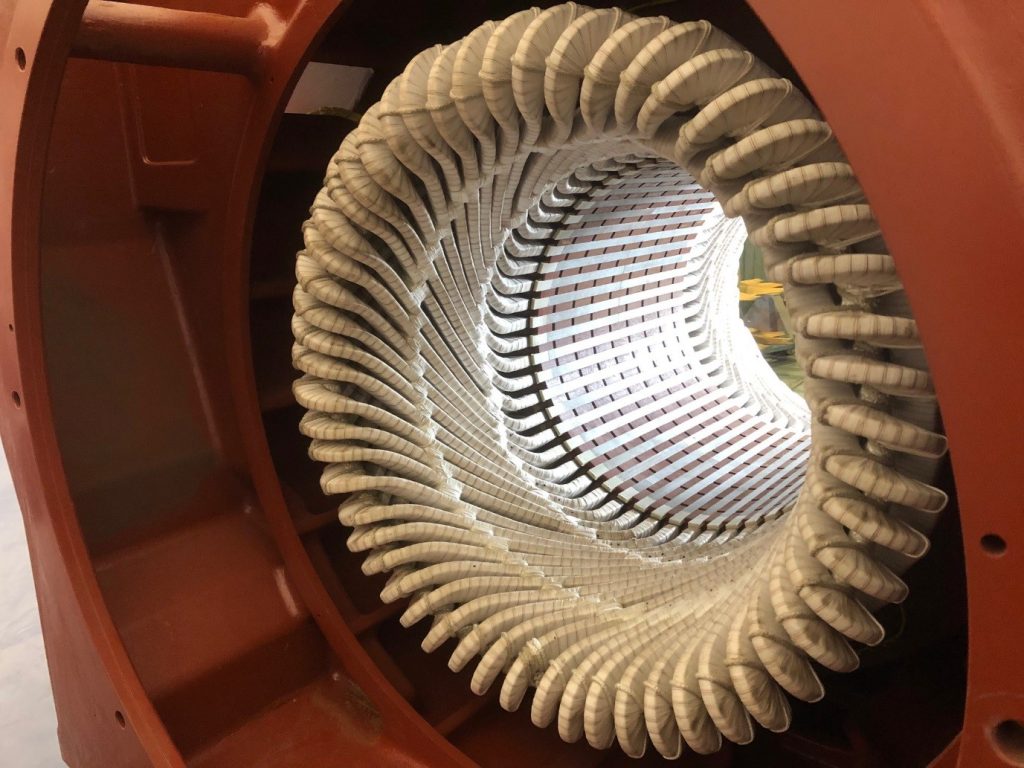

Upon the order being placed, a sample coil from the failed motor was received into Houghton International’s coil manufacturing facility. Upon inspection, it was evident that the coils’ original insulation was a global VPI solution (Vacuum Pressure Impregnation). Houghton International recommended its unique HiFLEX insulation system to eliminate any partial discharge emanating from the coils as each individual coil is fully tested at point of manufacture, guaranteeing dielectric integrity and ensuring there are no faults in them before the winding process.

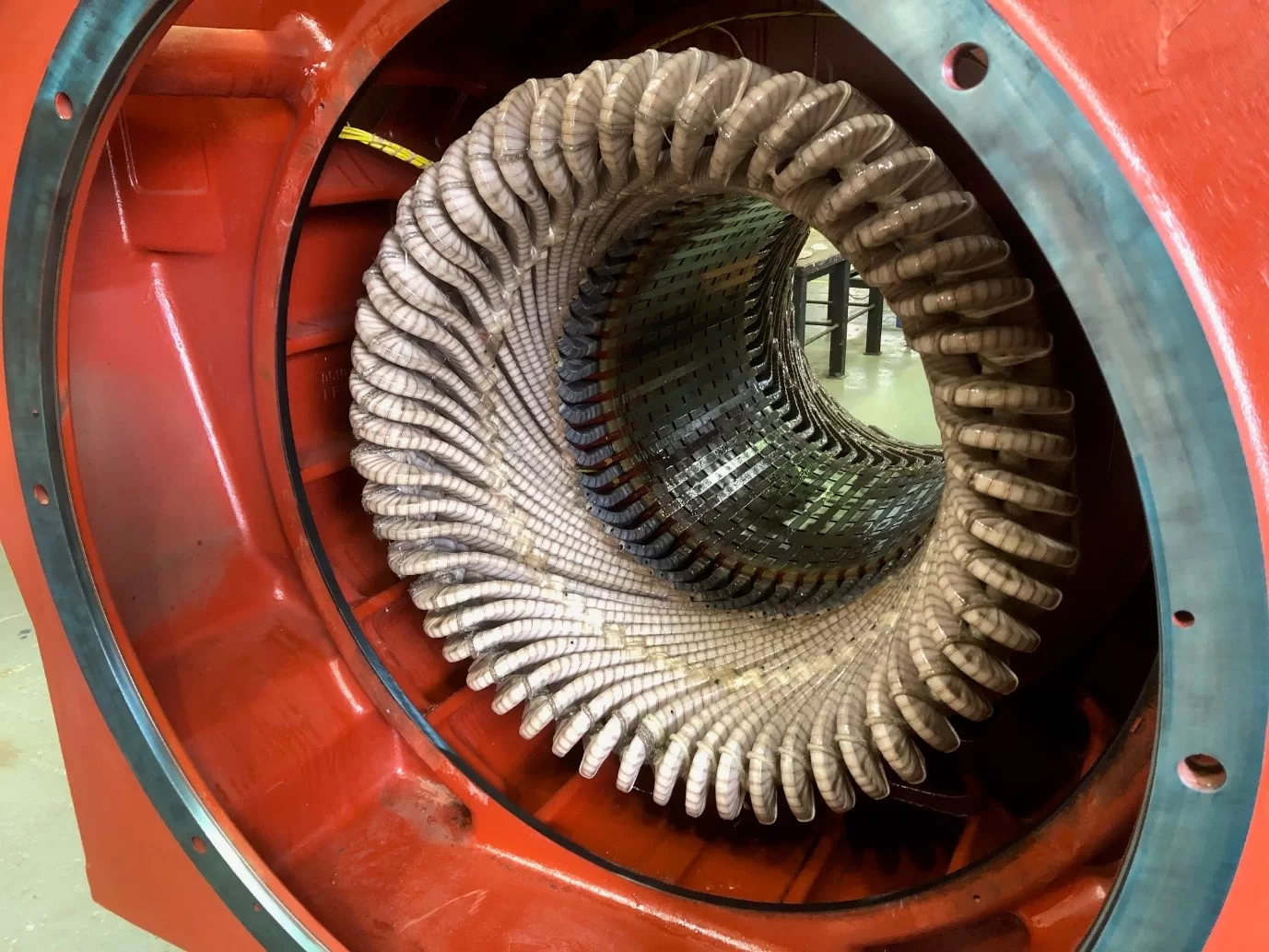

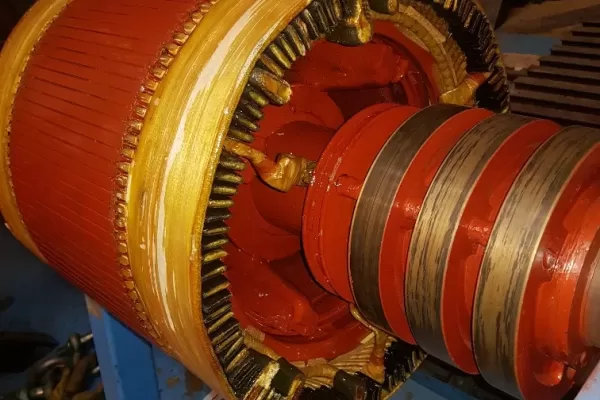

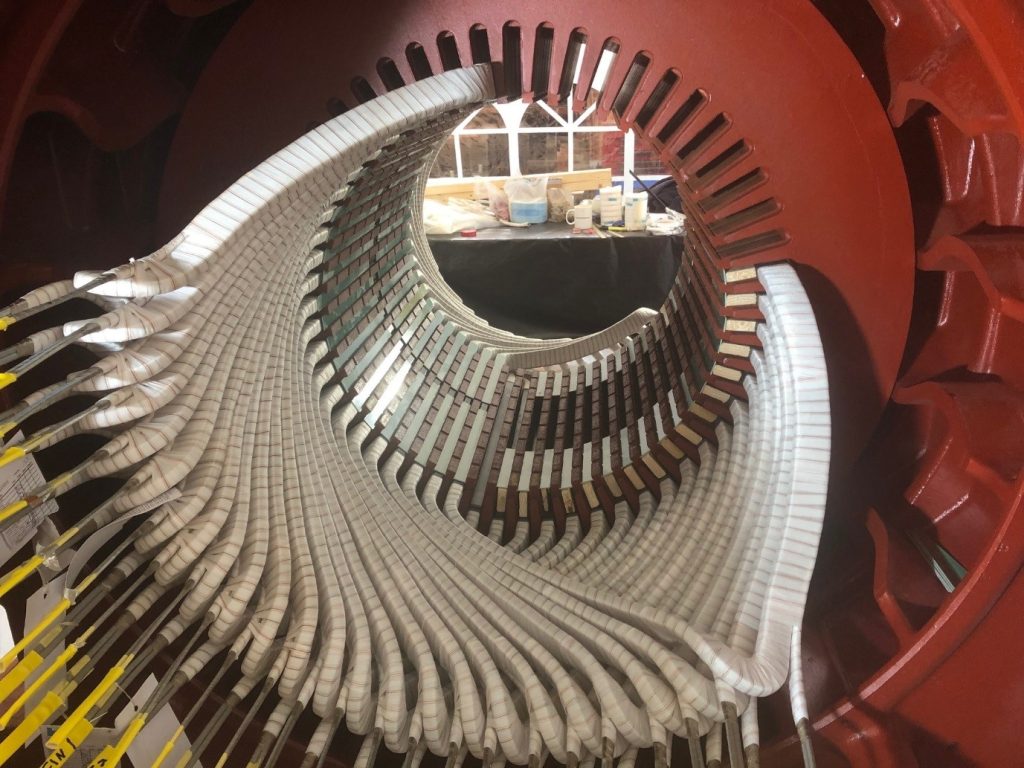

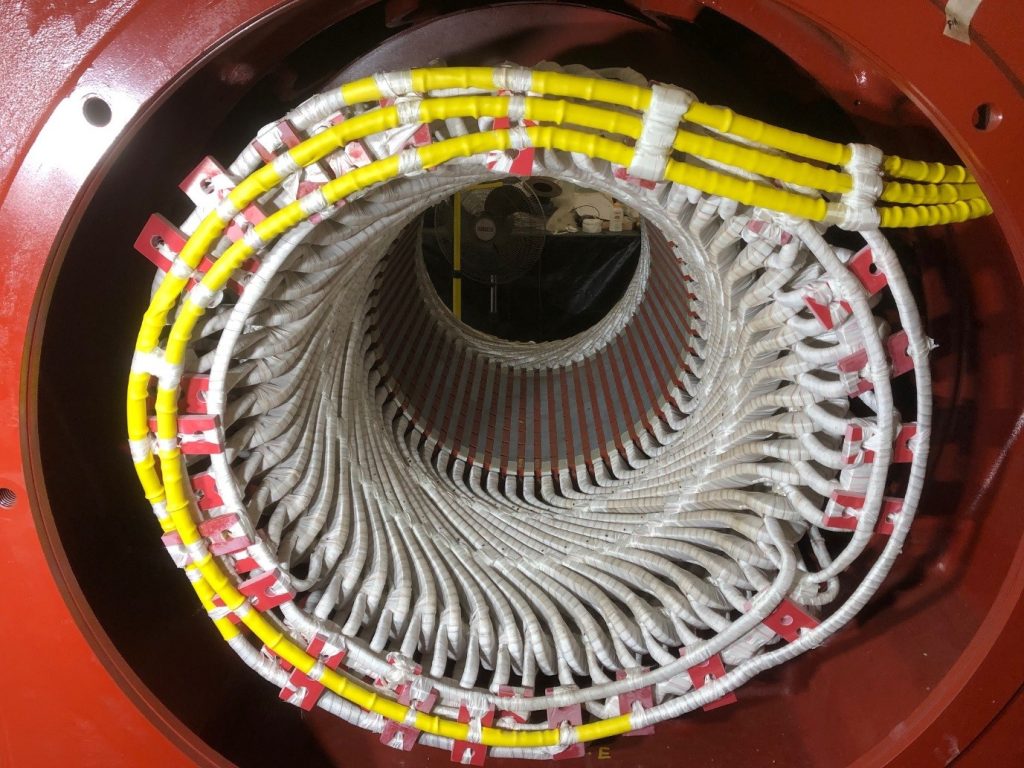

Upon customer approval, 54 (+2 spare) fully cured and fully flexible 11kV HiFLEX diamond coils (with 9 turns per coil) were manufactured at Houghton International’s in-house coil manufacturing facility. All coils had a hot-pressed resin rich cell with flexible outhangs, corona protection and stress grading tape applied to them. Furthermore, being a 2-pole arrangement, the gap between coils is significantly less than other standard rewinds but the HiFLEX insulation system overcame this issue because of total flexibility in the coil extension.

Coils were quality assurance checked and subject to a comprehensive testing schedule, including Hi-Pot testing, Tan Delta and interturn testing to measure the dielectric integrity and insulation of the coils. A partial discharge test was also carried out on each coil as they were manufactured. Partial discharge was controlled to less than 300 pc (Pico Coulombs) giving Reads Electric the confidence that a much longer life expectancy can be achieved and the security that any partial discharge emanating from the coils in the wound motor is eliminated.

Why Houghton International

Related Services

The Results

Houghton International provided the technical assistance and support sought by the customer and provided everything necessary for the rewind such as an auxiliary winding kit. This would give the customer peace of mind that the rewind process was completed easily, accurately and safely, avoiding any potential issues with partial discharge.

As an additional option for this particular job, the supplied slot wedges would normally have a two-piece profile, G11 and magnetic but to improve efficiency and make the unit work better, a one-piece magnetic profile was supplied.

All coils were packaged in a foil vacuum sealed bag system, inside a moisture proof wooden crate ensuring that they are not damaged throughout their expedited transit to Reads Electric’s facility in Western Australia. With the added benefit of having excellent relationships with a range of global freight operators, Houghton International were able to ship the coils on time and cost effectively.

We are extremely pleased with the set of HiFLEX coils supplied by Houghton International. Our winders were happy with the flexibility in the coils and made the rewinding process easier, especially this being a 2-pole motor. It was also evident in the partial discharge report that the coils supplied produced excellent test results which is a true testament to the high-quality HIFLEX coil design.

Mark Wilson, General Manager, Reads Electric Company

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.