Trusted By:

Featured Services:

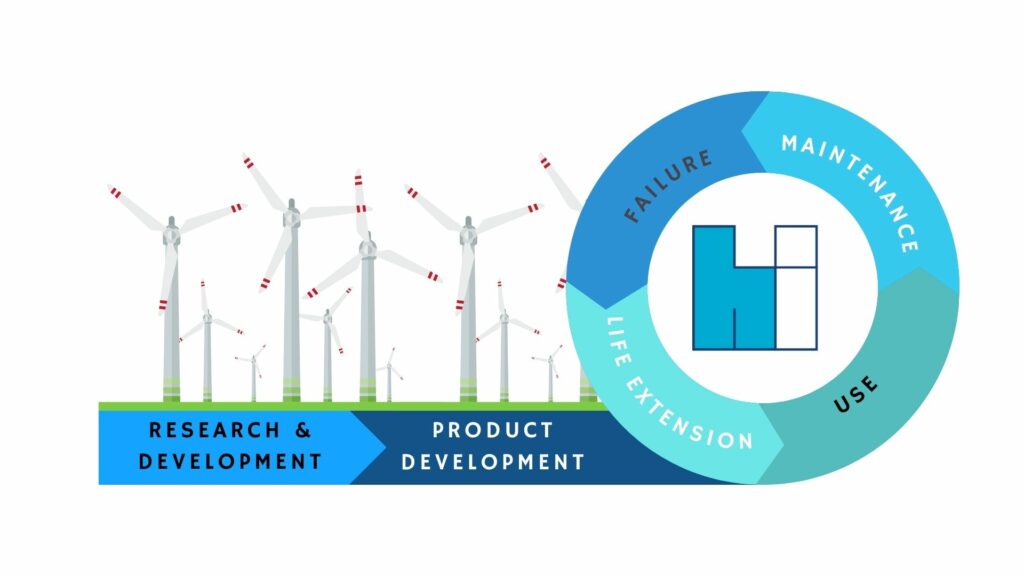

One-Stop Repairs and Maintenance For Wind Turbine Infrastructure

Explore our range of specialised services tailored to enhance the performance and longevity of critical assets in your wind energy infrastructure. From generators and motors to transformers and fans, we offer expert solutions to ensure optimal efficiency and reliability, empowering your wind farm for sustained success.

End-to-End Wind Sector Support

Discover our comprehensive suite of services tailored to meet all your wind energy needs. From meticulous testing and crucial support services to expert mechanical solutions and efficient up-tower maintenance, we offer a holistic approach to optimise the performance and reliability of your wind turbines

Trust us with your wind turbine repair and maintenance.

37.4%

Less global-warming potential

39%

More cost effective

66.6%

Less downtime impact

100%

Customers in this sector would use us again

Enercon E44 Wind Turbine Repair and Life-Extension

Grannell Community Energy

Frequently Asked Questions

Ready to optimise your wind energy infrastructure?

Get in touch using the boxes below and we’ll get back to you.