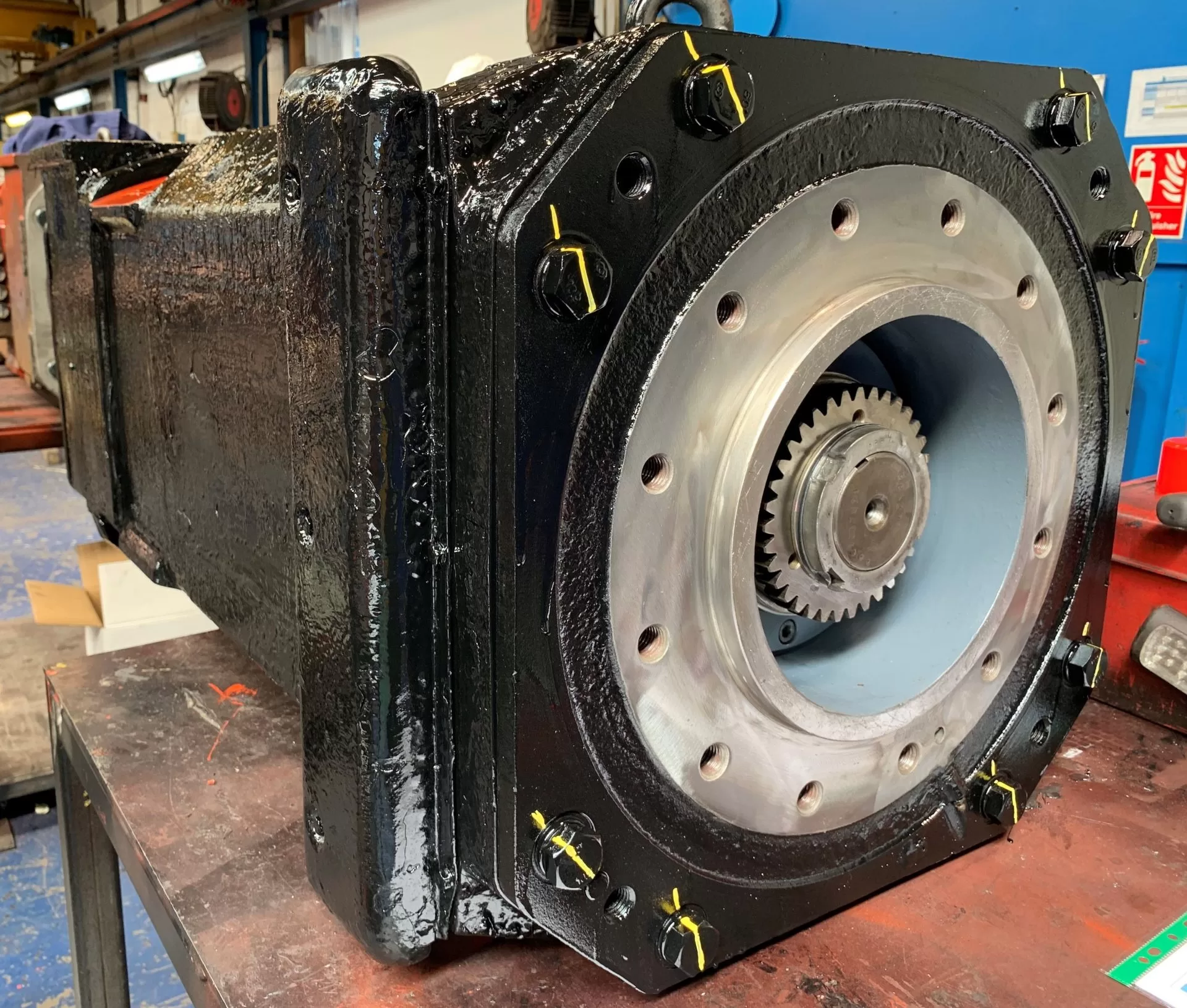

Houghton International’s RISAS-approved rail division specialises in the repair, maintenance and life extension of electro mechanical assets into the UK and global markets, including AC and DC traction motors, train alternators, generators and motor alternator sets.

With over 30 years’ multi industry experience in electro mechanical engineering, we provide:

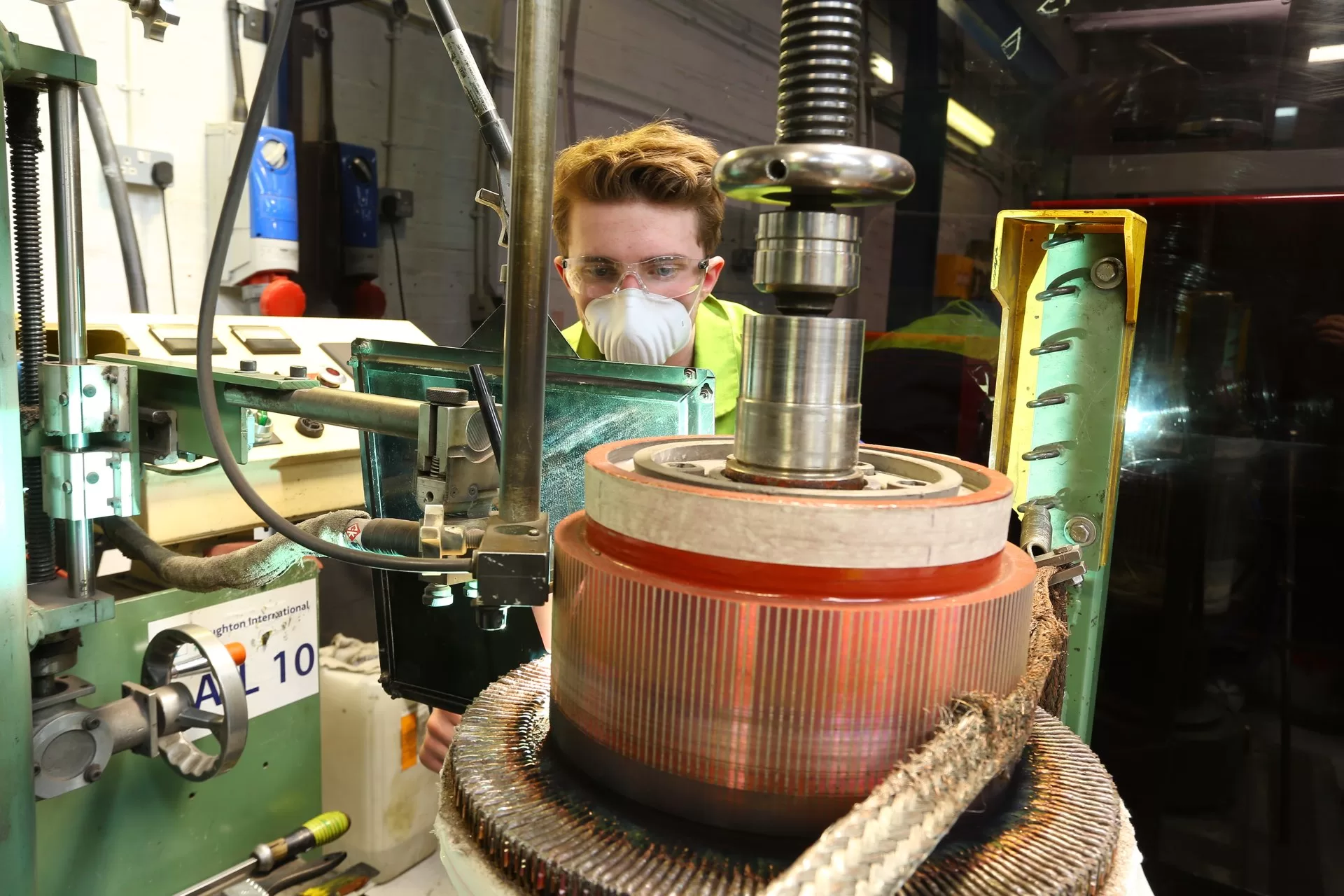

- AC and DC traction motor repair and overhaul – using our HiTRAX insulation system designed for optimum performance in rail operating conditions

- MA sets test and repair – comprehensively tested with our unique HiTRANS patented transient dynamic load test process which simulates full load conditions for train alternators

- High Speed Train alternators, DC line inductors, fan units, pumps and other auxiliary equipment and heavy repairs

- In depot services including visual inspection and fault finding in situ, static testing of equipment and commutator profiling

- Consultancy services; engineering and technical support, development projects and training

- Rail freight services – repair, maintenance and life extension for the rail freight industry

We work collaboratively with ROSCOs, TOCs, FOCs and bogie overhaulers to improve reliability and reduce costs by solving complex engineering problems and extending the life of electro mechanical assets across the whole vehicle.

We work with OEMs to support the introduction of new vehicles into the market and are TSA’s UK and Ireland service partner, offering local support and specialist repair services.

Experienced in both long-term volume overhaul contacts and one-off casualty repairs, we utilise our well-established supply chain, fully equipped rail facility and multi-skilled staff to mobilise effectively and deliver in line with customer requirements.

Having worked extensively on passenger vehicles both underground and overground, light rail, trams and freight vehicles we have a range of experience including one-off engineering projects, specification reviews, design projects and training.

- Passenger trains

- Light rail, tram and metro services

- Freight vehicles

We are the UK’s only rail traction motor repairer with the capability to rewind and vacuum pressure impregnate (VPI) both epoxy and silicone resins. Our AC motor test rig can also dynamically test all AC railway traction motor specifications. Utilising rotor bar crack detection equipment and automated TIG welding and undercutting equipment our quality processes are second to none. Furthermore, all traction coils are manufactured and tested in house, in our dedicated coil manufacturing facility, ensure full control over quality and delivery.

Specialising in the maintenance of both new and ageing assets, we also work with OEMs to support the introduction of new vehicles into the market. Providing troubleshooting, installation support, in situ condition monitoring and ongoing maintenance across the network.

Please contact us to find out more about how we can support reliability and safety targets to improve public performance measure (PPM) whilst reducing the life cycle cost of your assets to increase ROI.

Further Information

Related Services

Related Case Studies

Unipart

Tyne and Wear Metro

Contact us for more information on our rail industry services

Get in touch using the boxes below and we’ll get back to you.