The challenge

Houghton International had previously worked with Tyne and Wear Metro from 2007 to 2015 to overhaul their fleet of traction motors, utilising our HiTRAX system. In this time, we handled around 400 traction motors, ranging from standard overhauls to full rewinds as well as in-service failures.

Several years after the Houghton International contract came to its end, Tyne and Wear Metro approached us, seeking assistance due to problems with ongoing repair and maintenance, motor reliability and in-service failures. Over 20 vehicles were out of operation due to traction motor issues.

The solution

Houghton International mobilised in less than four weeks in order to get vehicles back in service. As a result of our existing knowledge and experience working with the motors, we were quickly able to allocate resources and start work.

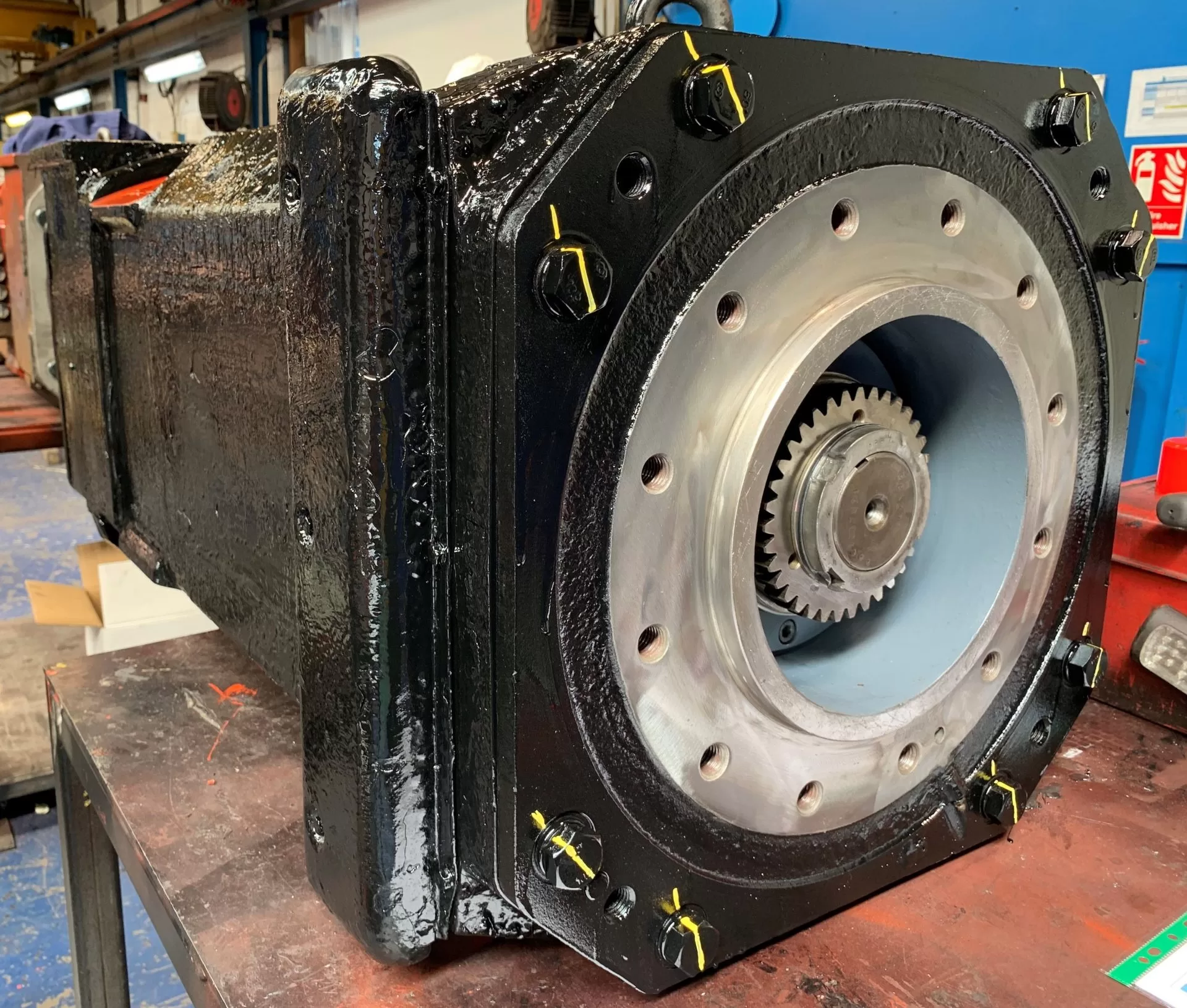

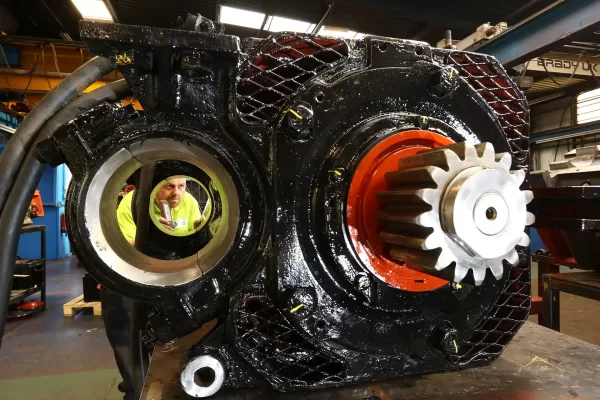

Each motor was dismantled, inspected and tested, following the process that Houghton International had designed and developed specifically for Metro traction motors. Tyne and Wear Metro were then provided with inspection reports and costings before repairs commenced.

Why Houghton International

Related Services

The Results

Having previously overhauled the traction motors, we were able to quickly set up with the tools and equipment to start work. Once work started at Houghton International, the first motor was returned within 10 days, mitigating further disruption to the Metro service.

We have carried out work on Metro traction motors for over 10 years so the processes and procedures for the repair and maintenance of the motors have become embedded across the business. They have been subject to continuous improvement, refined and optimised over this time

Where motors required a rewind, all coils are manufactured on site, giving us full control over the manufacturing process and quality assurance. To reduce the lead time before rewinds could begin, we allocated resources and quickly resumed manufacturing of the traction motor coils.

Since contract award, Houghton International has delivered the contract as agreed, mobilising within the agreed time period and supplying the overhauled traction motors as per the agreed schedule to an excellent standard. Overall, the team at Houghton International demonstrated a great deal of professionalism throughout the contract and there was exceptional communication throughout, providing us with up to date information of progress.

We look forward to continuing our relationship with Houghton International in the future, having demonstrated a great deal of competency on both planned overhauls and urgent repairs.

Marc Robson, Heavy Production Manager, Nexus

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.