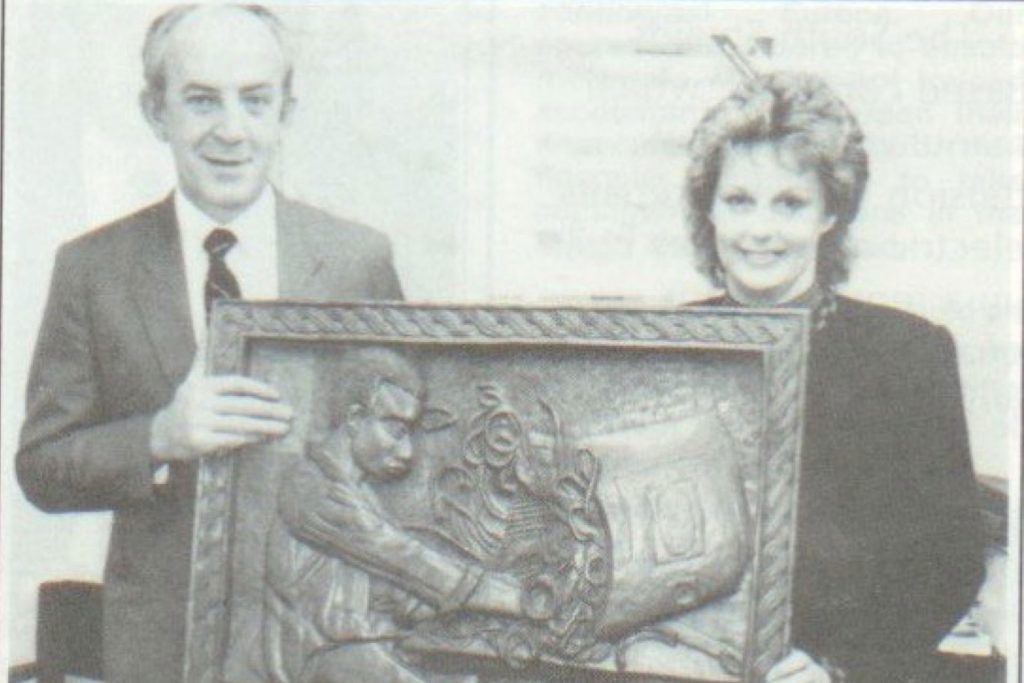

1984 – 1989

Houghton International was founded by Ron and Christine Mitten in 1984 and was set up to supply coils to Portland Electrical Repairs in Nigeria. The company was originally based in Houghton-le-Spring, which inspired its name. After a few years of steady growth, the company moved to larger, more modern premises in South Shields in 1988 and set up as one of the most advanced coil manufacturing and motor repair facilities in the UK. Just a year later, Houghton International won an export order to Hong Kong, increasing their global footprint and were awarded the prestigious BS5750 mark of quality for both coil manufacturing and rewind and repair work.

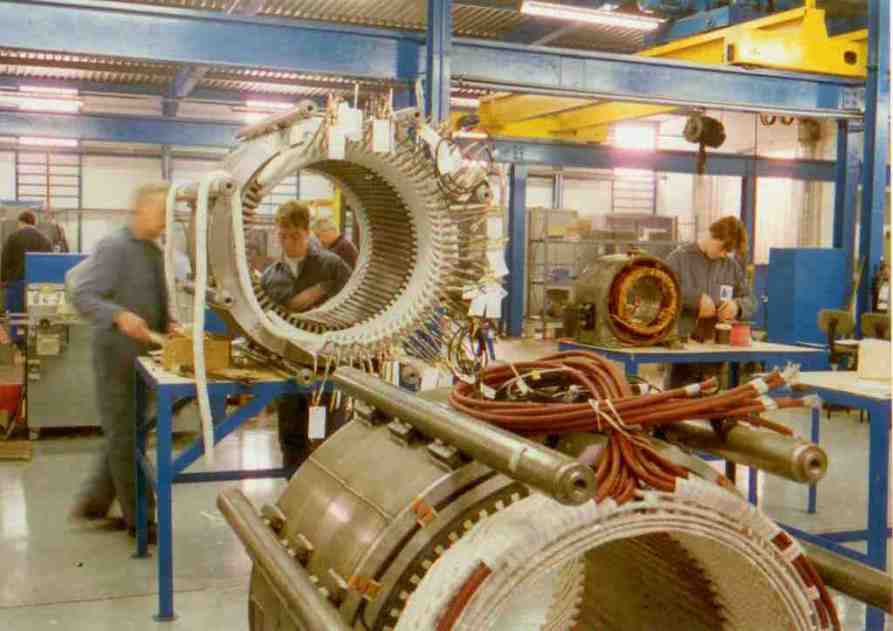

1990 – 1999

In 1994, Houghton International expanded and moved to its present site in Newcastle upon Tyne. Over the years, its innovation and reputation for quality within the industry has gone from strength to strength and Houghton International prides itself on the relationships it has built with its clients. During this time, Houghton International has grown from one customer to over 400 in the UK and beyond and in 1999, broke through the £1m turnover barrier.

2000 – 2005

At the turn of the new millennium, Houghton International entered into the lucrative Texas oil market and won their first order for high voltage coils from the United States worth £15,000. In the same year, the company started manufacturing half bars for air cooled turbo generators up to 70MW. In 2001, Houghton International achieved another milestone, hitting the £2m turnover barrier and made the country’s top 100 fast growing companies in the Inner City 100 Index published by the Financial Times. A year later, the company, commenced rewinding AC traction motors for OEM’s and in 2005, opened a light traction motor rail overhaul facility and won its first rail contract with Unipart Rail. Furthermore, Ron Mitten was elected President of the Association of Electrical and Mechanical Trades (AEMT).

2006 – 2010

Michael Mitten was appointed Chief Executive Officer in 2006 and under Michael’s leadership, Houghton International quadrupled its turnover and trebled its head count. Three years later, the company celebrated its 25-Year Silver Anniversary by announcing the creation of 40 jobs, the acquisition of a second 10,000 square foot storage and production unit and the development of DC traction motor heavy repair services. In the same year, Houghton International were proud winners the of North East England Small Business of the Year Award. A year later, the company launched HiTRANS™ Transient Dynamic MA Set Load Test Process, a process which electrically simulates full load conditions of any type and replicates exactly what happens in service.

2011 – 2012

HV/HT Coil Manufacturing department moved into a newly opened purpose-built third facility, providing increased capacity for the production of high voltage coils, alongside investment into new machinery. In the same period, the company completed its largest single order for a leading international offshore services provider, a 17 tonne, 4.6MW 3500HP DC thruster motor on an offshore oil rig had been severely damaged due to flooding. The company’s Occupational Health and Safety Management System was accredited to OHSAS 18001:2007, enabling Houghton International to demonstrate that a system is in place for occupational health and safety.

2013 – 2015

In this period, Houghton International attained environmental management system accreditation to BSI EN ISO 14001:2004 and were awarded a patent for HiTRANS™, the company’s transient MA Set loading testing process (protected by UK Patent No. 2494369). In a series of award wins, the company won the SME Excellence Award at the 2013 Chartered Institute of Personnel and Development (CIPD) North East of England branch Human Resources and Development Awards and came out on top in the Apprenticeships category at the Tyneside & Northumberland heat of the North East Business Awards 2014. Houghton International also achieved the coveted Rail Industry Supplier Approval Scheme (RISAS) certification for rage of AC and DC traction motor and motor alternator (MA) set repair and overhaul services, demonstrating Houghton International’s commitment to the rail industry.

2016 – 2017

In 2016, Houghton International expanded into a fourth operational site in Newcastle upon Tyne. This 10,000 square foot large machine repair shop provided increased operational capacity, head room and 40 tonne cranage. Following this expansion, the company welcomed 10 new recruits to the team to keep up with demand and support further growth, boosting staff numbers north of 100 for first time in 30 years. A year later, Houghton International became an EASA accredited service centre by the Electrical Apparatus Service Association (EASA). That same year, Houghton International won the AEMT award for Contribution to Skills & Training for the innovative Houghton International Apprentice Programme and was also awarded the contract to overhaul of a 37-tonne steam turbine generator for one of the largest and most efficient coal-fired power plants in the UK.

2018 – 2019

Following an independent audit, the company achieved IECEx service facility certification, which demonstrates the capability to safely repair and overhaul equipment used in explosive atmospheres. Success also came in March 2018 as Houghton International scooped the top prize in the Services category at the North East Business Awards. The business was commended by the judges for its innovative culture and going above and beyond to develop solutions to customers’ problems. Continuing with its expansion and to keep up with the needs of the industry, Houghton International developed a dedicated pump service and testing offering and appointed a new Head of Pump Services to grow its offering.

2020-2021

Following continued expansion, which at one point saw Houghton International occupying six separate sites in the Walker and Heaton areas of Newcastle upon Tyne, the business relocated to the historic CA Parsons Works in Heaton in order to consolidate the business and create a best in class facility from which to service its growing domestic and international customer base. The facility was officially named the Ronnie Mitten Works, in recognition of one of the founders of the business, whose technical legacy lives on within the business to this day.

2021-2022

In 2022, Houghton International was crowned SME of the Year at the Make UK National Awards. SME of the Year is awarded to businesses who have shown exceptional initiative, boldness and dynamism, as well as exemplary management practices. Houghton International was commended for demonstrating such criteria through their considerable investment in employees, offering a range of training and development opportunities as well as various staff benefits such as a ‘Sharing Success’ staff bonus scheme.