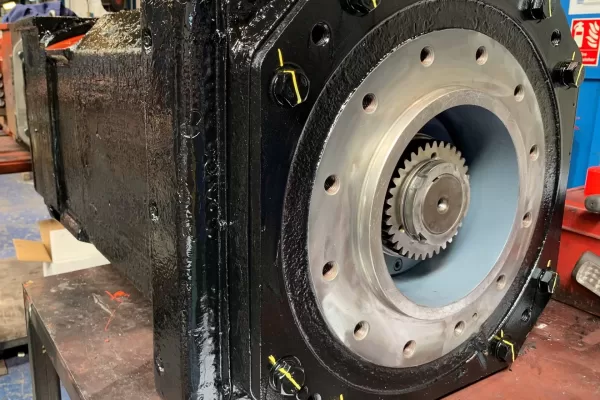

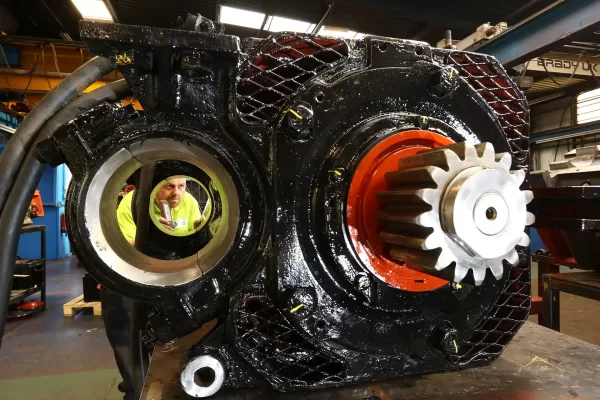

As part of the contract with GWR, Houghton International has carried out over 100 overhauls of their Class 43 HST alternators.

The challenge

In March 2016, following a successful tendering process, Houghton International was awarded the contract for the overhaul of the GWR Class 43 HST Alternators, moving the work from the incumbent supplier and actual alternator OEM.

The initial tender requirement from GWR was for an alternator overhaul only, however based on our tender submission we were able to demonstrate our technical capability of managing the entire overhaul process and were further awarded the management of the full powerpack overhaul.

The contract was for the overhaul of 110 HST powerpacks over a 2 and a half year period, including emergency repairs, life extension and coil manufacture and rewinding.

Houghton International was successful in consistently delivering the schedule set out by the customer in their QL4 programme – with 100% on time delivery. The only company in the history of the overhaul programme to achieve this.

The solution

Following contract award, Houghton International was able to mobilise and scale up to successfully deliver the overhaul contract in a short space of time. Facilities were established, processes and procedures developed, and stock ordered to enable a smooth transition and facilitate contract ramp up. Working closely with GWR and the engine overhauler, Houghton International carried out overhauls in line with the QL4 programme and provided emergency support / repairs as required.

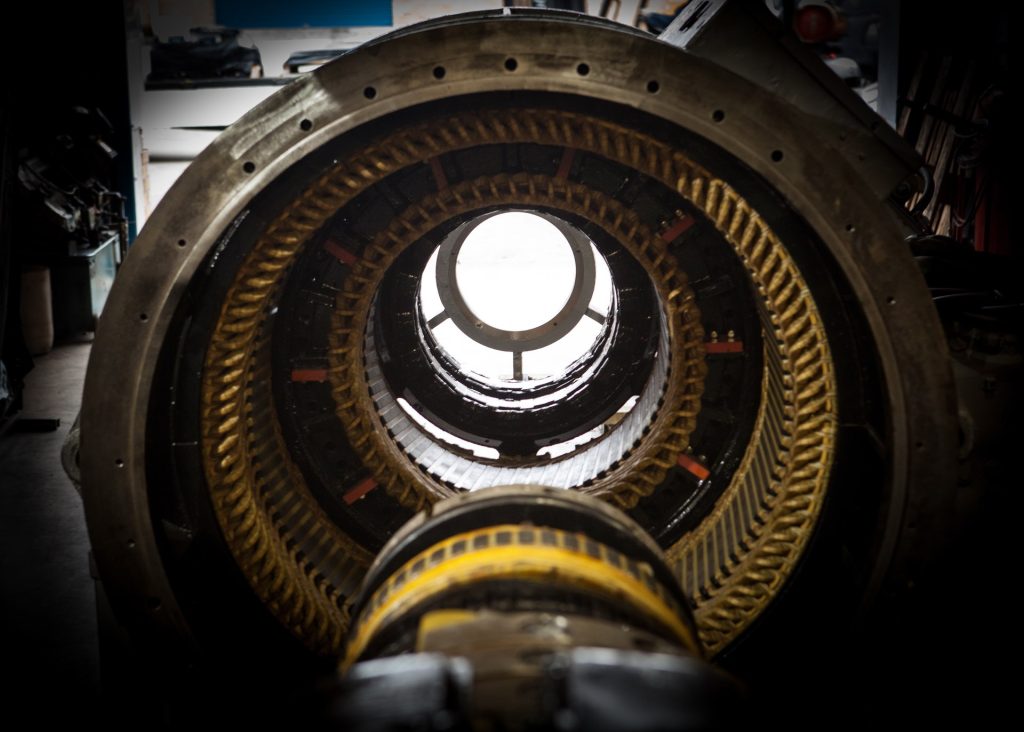

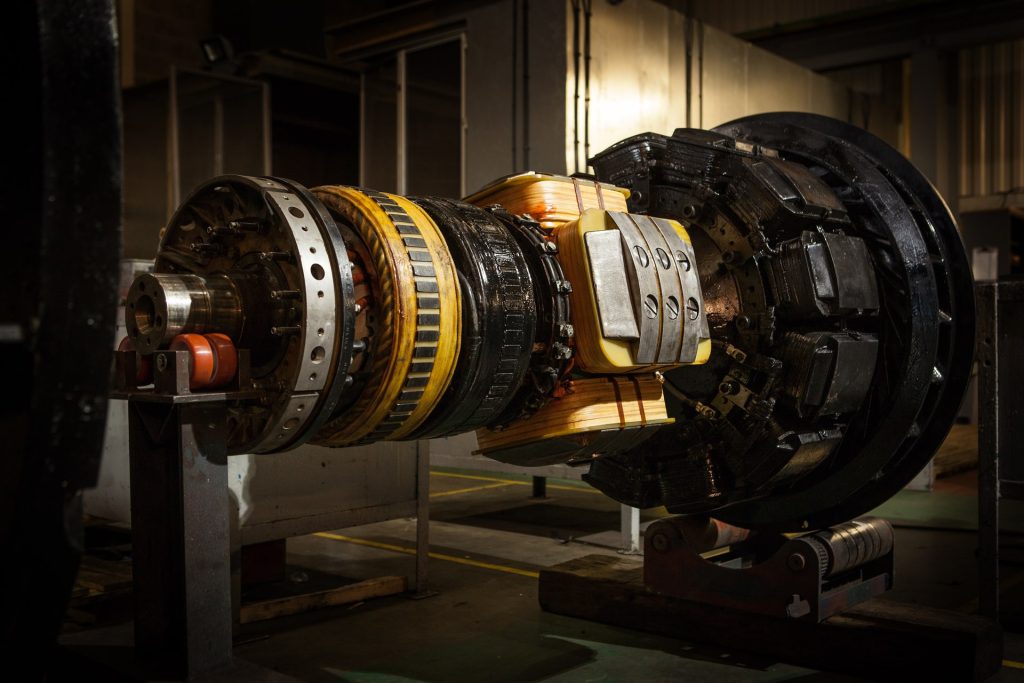

Initially, Houghton International was given the opportunity to demonstrate their technical electro mechanical capabilities on an initial one-off alternator repair. The alternator, 019A, had suffered a catastrophic in-service failure. As instructed by GWR, Houghton International undertook a full repair which consisted of a full main stator rewind, a full auxiliary stator rewind, the rewind of the four auxiliary rotor coils and the rewind of the auxiliary exciter rotor to requested specification.

Houghton International identified an original winding fault with the first alternator received for repair. During final stage testing of the alternator, the auxiliary exciter rotor was showing an unbalanced phase through the AWA 12kV Baker tester. Following further investigation by the team at Houghton International and examination of another alternator in situ at Swansea’s Landore depot, which was also showing an unbalance, it was suggested that there could be a potential improvement to the original manufacturers’ design. After consultation with GWR and subsequent approval, the auxiliary exciter rotor was rewound to the updated specification, recommended by Houghton International to balance the rotor winding.

After extensive testing, the alternator was re-fitted on the train. Initial indications show that the HST alternator is now running cooler which would suggest that it will generate more power and improved performance. The fault and subsequent improvement were identified through standard ‘added-value’ specialist Houghton International expertise. This had now led to a permanent quality and performance improvement across GWR and other HST users.

Why Houghton International

Related Services

The Results

Houghton International successfully delivered the complete overhaul contract, ranging from standard overhauls to full rewinds, consistently delivering the schedule set out by GWR in their QL4 programme – with 100% on time delivery to the quality standards required. The only company in the history of the overhaul programme to achieve this.

GWR benefited from a high quality and reliable service, enabling them to optimise their planned maintenance schedules and minimise the effects of failures and unplanned maintenance activity. Efficiency was improved and performance levels maintained, supporting GWR to run a reliable service.

Since contract award, Houghton International has delivered the contract as agreed, mobilising within the agreed time period and supplying the product as per the agreed schedule to a high quality. Contract management via Chris Lisle and Chris Robson has been effective and any issues have been dealt with in a timely and collaborative manner. The operational and technical teams have met the high standard required by GWR and I would not hesitate to recommend them for future work.

Phil Gray, Fleet Engineer, HST & Loco, GWR

128

Successful alternator overhauls completed

100%

on time delivery

108 coils

per Class 43 armature

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.