Implementation

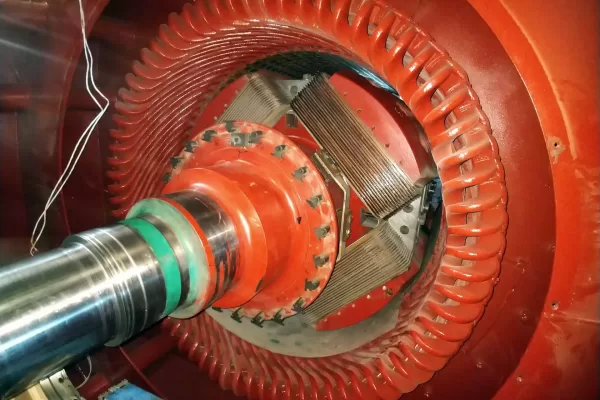

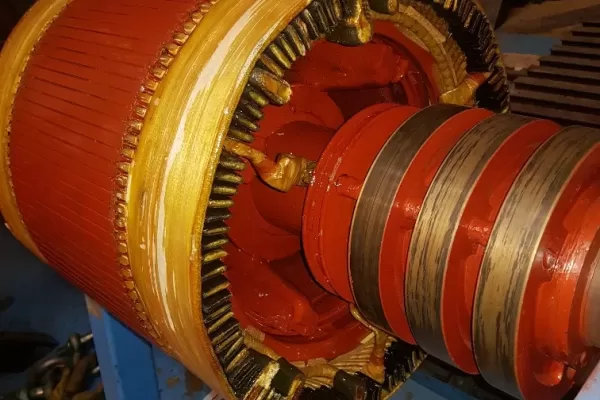

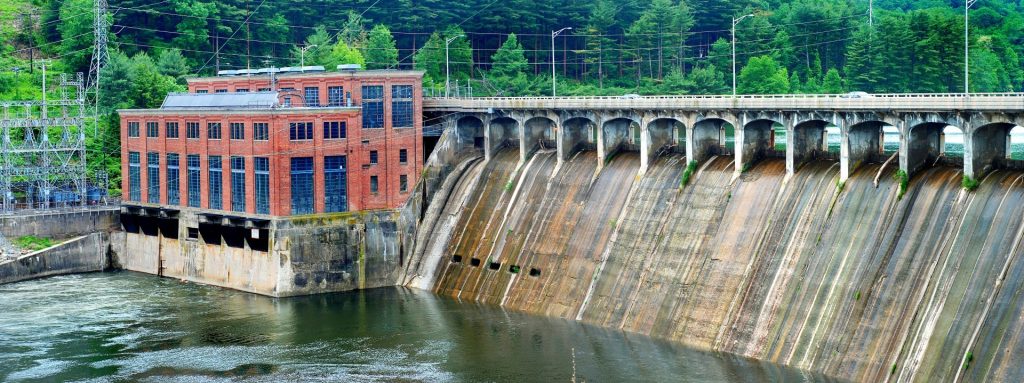

The technical teams at Houghton International and Leppert Nutmeg worked in collaboration to produce a coil design that updated the specified design and materials. We also upgraded the coil insulation system from class B to class F for better dielectric strength and a longer service life. We manufactured a full set of 288 +2 6.6kV coils using our HiDro coil design, specifically developed to meet the design specifications of Hydro applications.

Overhaul

Houghton Internationals’ Autocoil software was used to produce 3D coil designs and slot build drawings to clearly communicate the coil design and ensure accurate fit. The coils were subject to extensive testing. Sample coils were tested for voltage endurance for 1200 hours, 3 times longer than required by the IEEE 1043 standard which extrapolates to over 30 years in service.

Outcome

After VE testing the coils passed further electrical testing including Tan Delta and partial discharge tests, giving confidence in service life. All coils were subject to HiPot, Interturn and Tan Delta testing prior to dispatch and further testing recommendations were provided to the customer for testing during and after winding. The coils were vacuum sealed and packaged back to the USA to the customer.

Houghton International manufactures high quality coils with low PD that are always consistent.

Leppert-Nutmeg has completed numerous projects using high voltage coils designed and manufactured by Houghton International. As Houghton International are experienced in both winding and coil manufacturing, when our winders ask for certain design features Houghton International understands and can provide useful feedback.

William “Mike” Marion, Leppert Nutmeg

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.