The challenge

Houghton International was awarded an order for a full overhaul of an aged and complex motor. A non-standard motor with no nameplate information meant that parts would need to be reverse engineered and that experienced technicians would need to wind this job. The full scope of the works included the manufacture of coils, rewind of the rotor and stator and assembly and full testing of the complete motor before recommissioning.

The solution

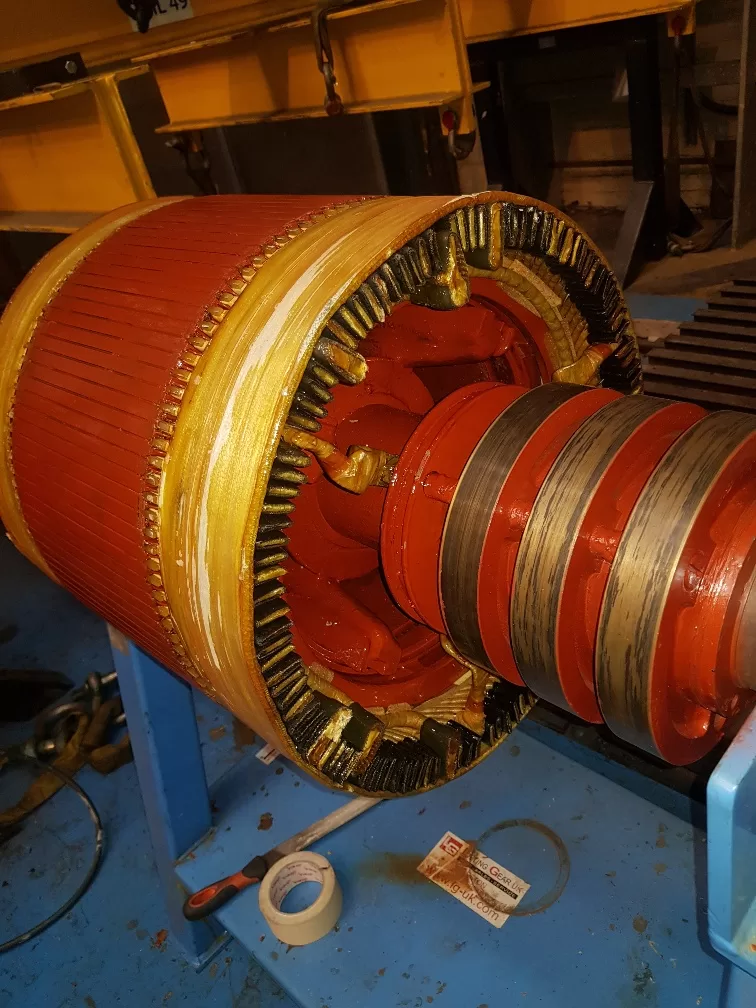

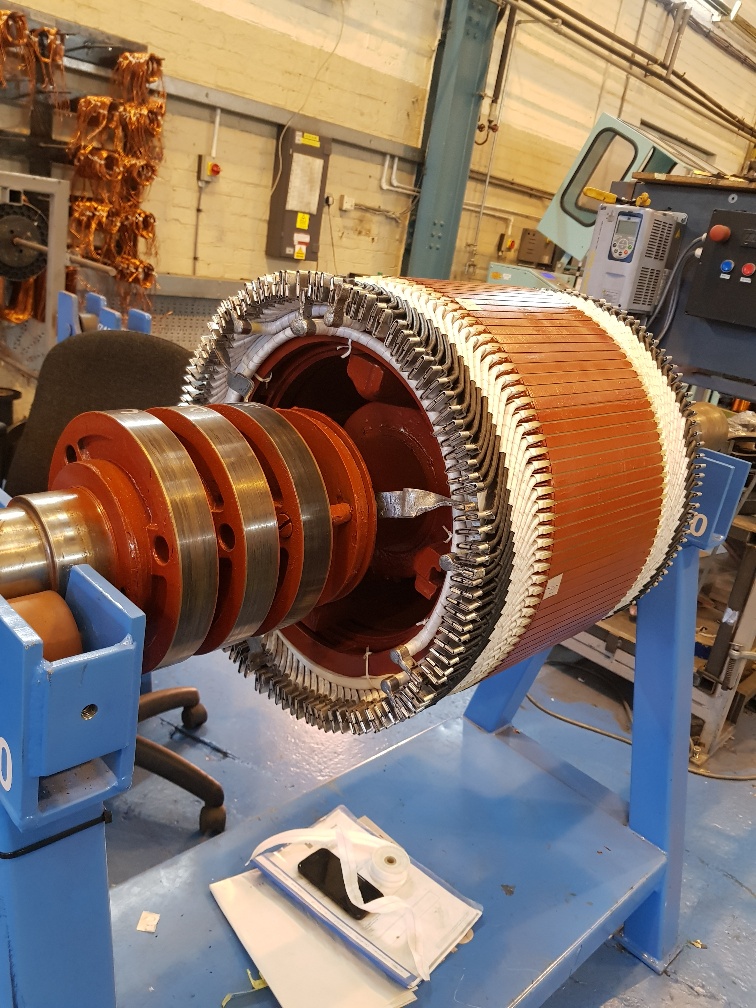

After the collection of the motor from the customer’s site and receiving of it into Houghton International’s IECEx certified large machine shop, an initial inspection was carried out by the engineering team to better understand the condition of the windings. Existing windings for both the rotor and stator were stripped out (retaining clips for refurbishment), slots were cleaned, and a core flux test was carried out. Based on the initial inspection and preliminary work, Houghton International carried out a full overhaul of the motor.

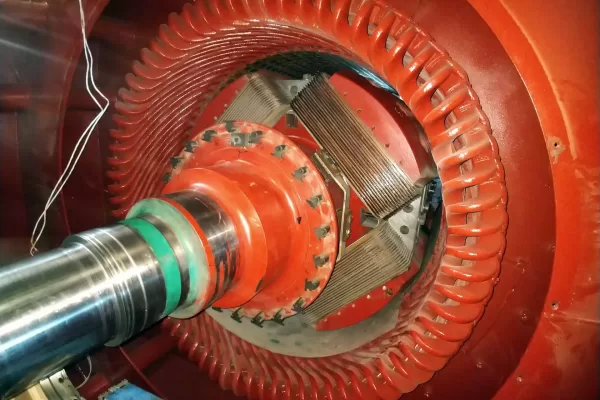

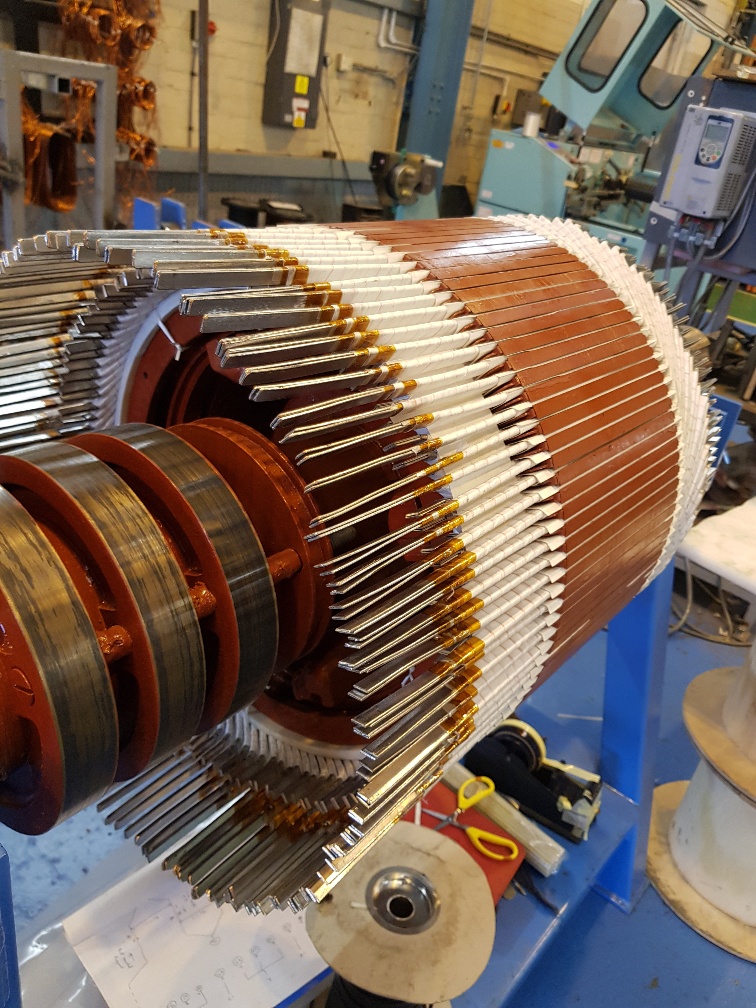

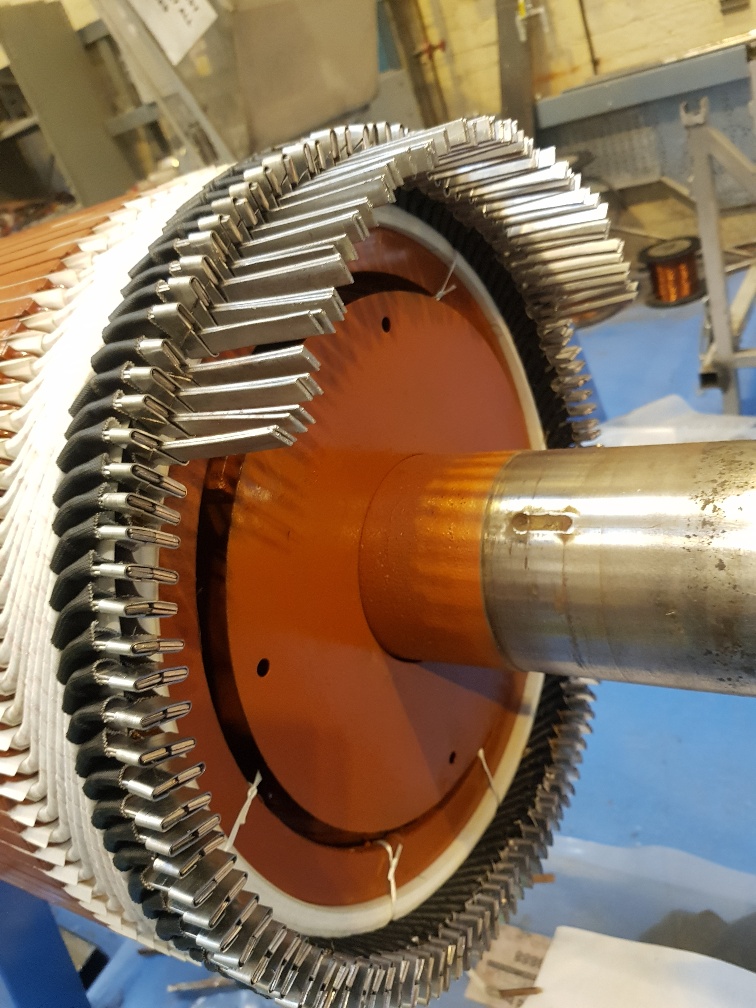

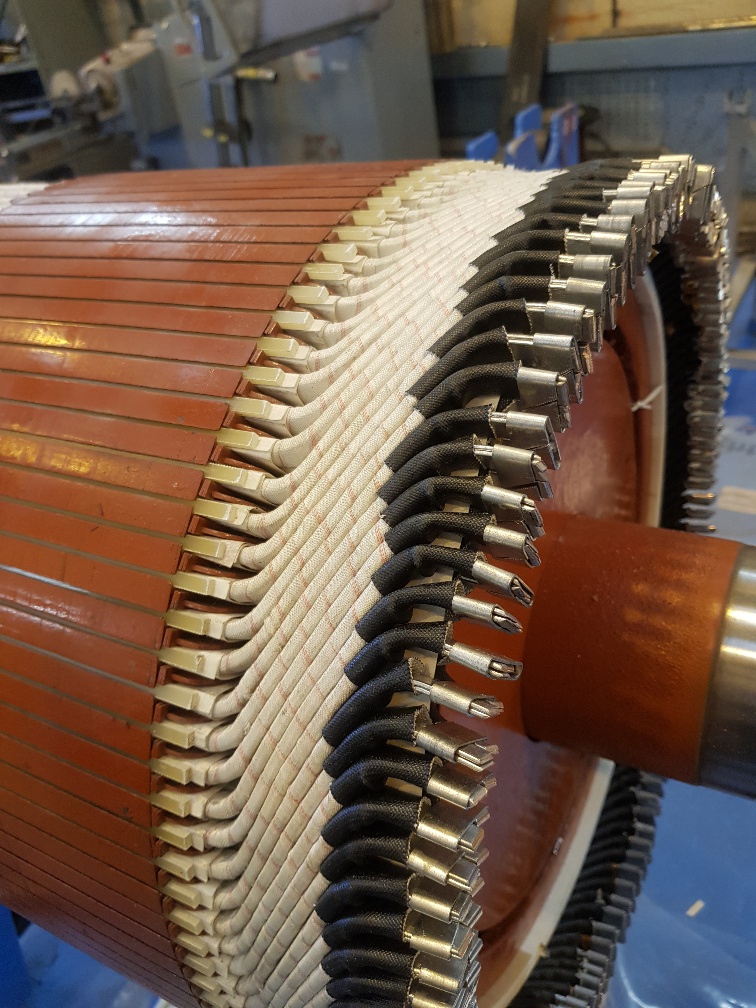

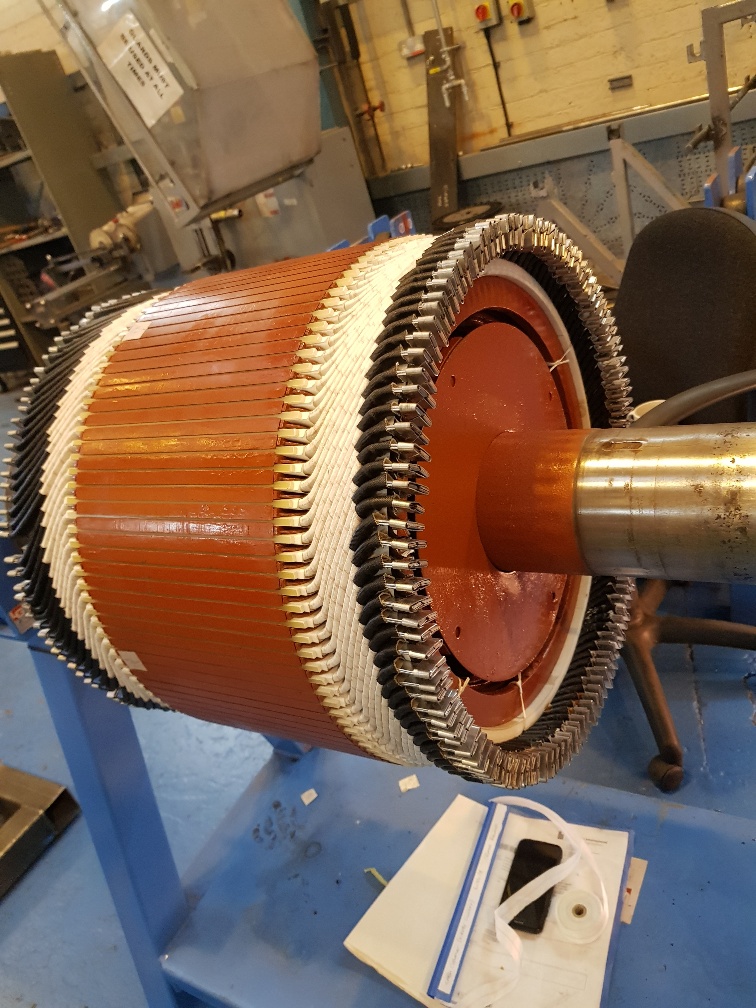

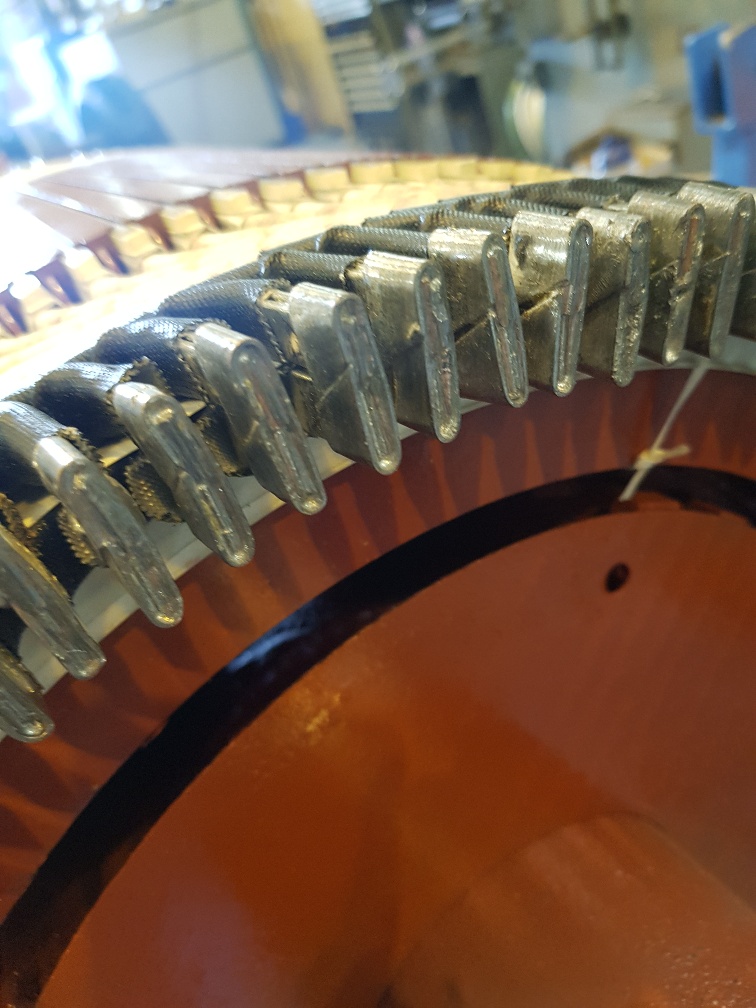

72 push through coils, comprising of Houghton International’s HiVAX insulation, for both the rotor and stator were manufactured at Houghton International’s in-house coil manufacturing facility. All coils were form wound and insulated with glass reinforced modern mica tape and modern insulation to improve efficiency. The coils were then wound into the rotor and stator core using a push method because the slots were enclosed. Connections were then made and insulated, and the skinned and buffed coil ends were blocked and soldered for support. The entire rotor and stator were then vacuum pressure impregnated (VPI) in an epoxy resin to fill gaps in materials to create a void free insulation

Following the rebuild, the rotor and stator underwent full testing including a Baker test which ran a complete cycle of tests to ensure the integrity of all windings. The rotor was then dynamically balanced to ISO grade 2.5. The complete motor was then fully quality assurance checked and made ready for dispatch back to site to be reinstalled and recommissioned.

Why Houghton International

Related Services

The Results

Due to its age, the motor was non-standard and defunct, meaning no direct replacement was available. This combined with the fact it was a push through motor, whereby coils are fed through by a push method through the slots rather than from the top because the slots are enclosed, it required a higher level of skill than in a standard winding method. With Houghton International’s knowledge, skills and expertise in repairing aged and complex mechanical equipment the motor was bought back up to specification and given a new lease of life.

Having the motor overhauled was a more cost-effective solution for the customer than buying a whole new motor. This is because if the new motor was changed, all ancillaries such as the shaft, couplings, gearbox, junction boxes would need to also change as these were designed based around the old motor. Furthermore, having the old motor overhauled meant that the original mounting facility could be re-used.

Additionally, with all of the complexity of the winding process, Houghton International completed the works within the timeframe requested by the customer and regular updates were provided, keeping them informed throughout the process.

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.