The challenge

A customer of Electric Motor Service Limited (EMSL), a paper pulp mill based in Canada, was looking to increase the productivity of their operations. To achieve that goal, they sought to increase the power output of a 13.8kV motor driving an industrial crusher that grinds wood to make paper pulp, from 18,000 HP to 20,000 HP.

EMSL placed an order with Houghton International to redesign the HV coil cross sectional slot build, manufacture, supply and assist with the rewind of 48 (+2 spare) high voltage stator coils.

The solution

Upgrading the motor with more power would involve a slightly more complex coil arrangement. Houghton International recommended that having two different wire sizes and two different turns would work to satisfy the space constraints in the slot. Moreover, by also adopting a modern insulation system for the coils, space could be gained enabling an upgrade of the motor as requested by the end user.

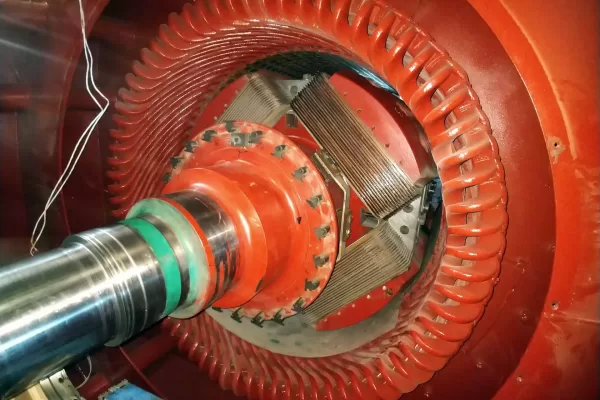

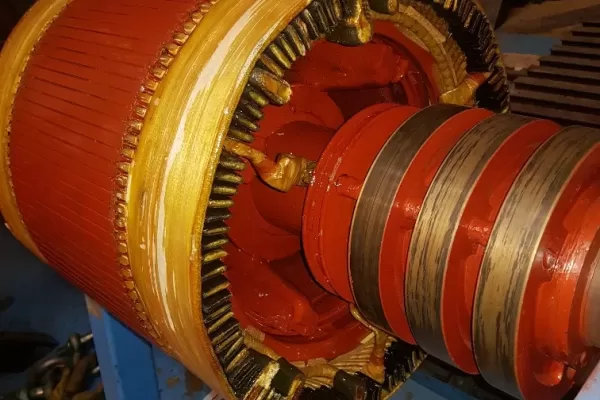

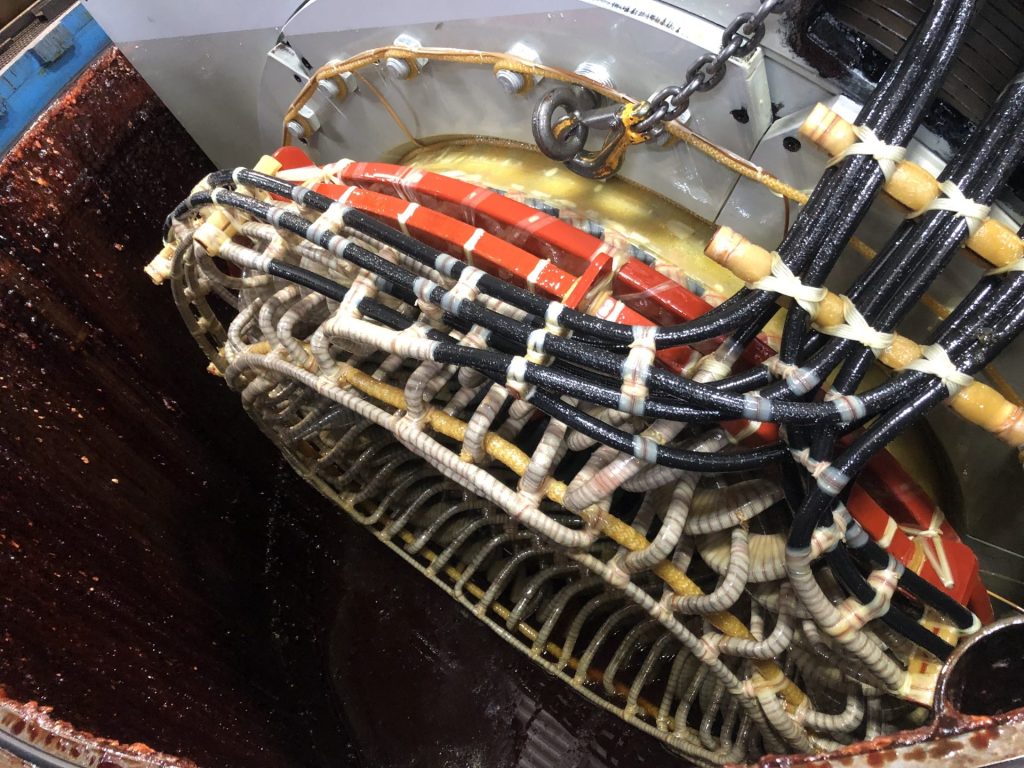

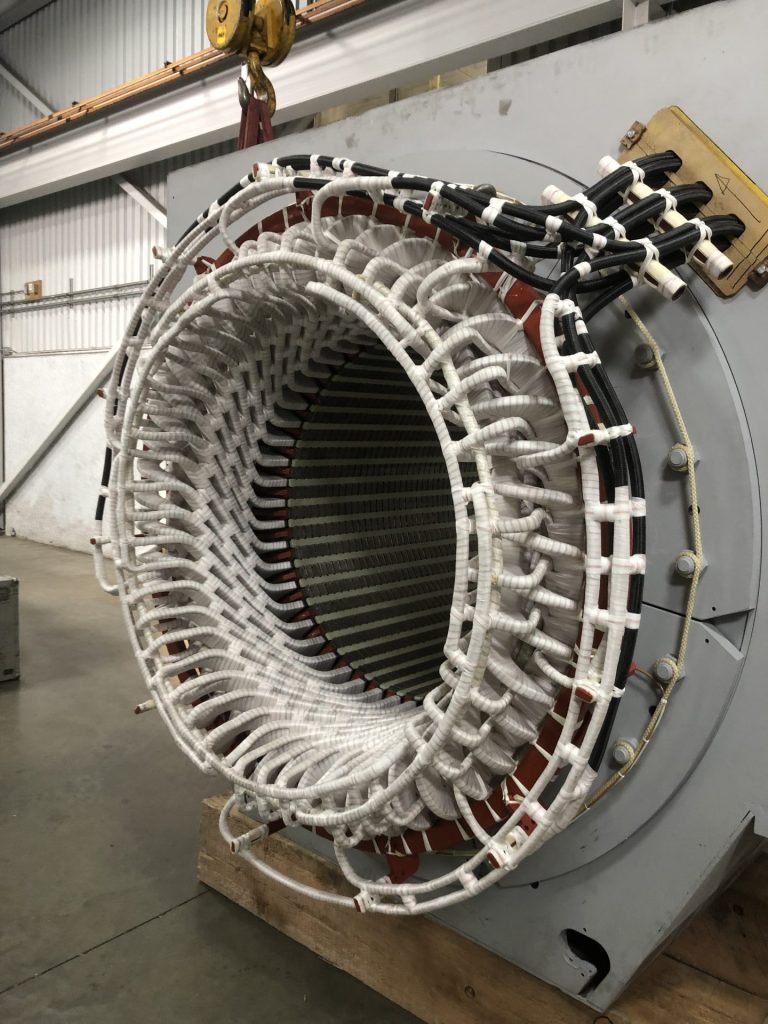

Using its AutoCoil design software that utilises the latest technology to offer 3D coil design and slot build drawings for improved design and accurate fit, a redesigned slot build was produced by Houghton International. Upon approval by EMSL, 48 (+2 spare) fully cured and HiFLEX coils were manufactured at Houghton International’s in-house coil manufacturing facility with bare wire sizes of 7.34 x 1.9mm (9 turns per coil) and 7.34 x 2.10mm (8 turns per coil) using 6 wires in parallel. Weighing 37kg each, all coils had a hot-pressed resin rich cell with flexible outhangs, corona protection and stress grading tape applied to them and insulated for 13,800V line voltage. Coils were then quality assurance checked and subject to a comprehensive HV testing schedule, including Hi-Pot testing at 34.32kV and interturn testing at 28.60kV to measure the dielectric integrity and insulation of the coils.

Before dispatch to EMSL’s facility in Canada, coils were packaged in a foil vacuum sealed bag system, inside a moisture proof wooden crate with copper connections and winding kit. The added benefit of ordering a winding kit from Houghton International is that with over 30 years’ experience and also being a repairer, we know the requirements, materials and equipment needed to complete a job of this size.

Why Houghton International

Related Services

The Results

As part of the project, Houghton International also provided a highly experienced winding engineer to offer supervision and support with the rewind of the stator upon the arrival of the coils at their facility. By working in collaboration with Houghton International on site guaranteed that the rewind was completed accurately and safely, avoiding any potential issues with the end user. Furthermore, boasting a fully cured and fully flexible insulation system, the HiFLEX system offered improved fit and therefore made the coils easier to install and reduced any risk of damage.

Additionally, as part of EMSL’s contract with their customer, it was stipulated that a 5-year warranty was provided on the entire rewind, therefore there was a clear benefit in working with Houghton International as they offered a 5-year warranty on their coils. As part of validating the warranty, Houghton International offered an aftercare service package to EMSL, subject to certain criteria.

It has been a pleasure working with Houghton International on this job. The level of service received throughout has been exceptional and the set of HiFLEX resin reach stator coils that they supplied to us were uniform in shape and size and were an excellent fit during winding.

Both engineers Houghton International sent to assist with the rewind in Canada demonstrated professionalism and attention to detail throughout their time with us. Our team really benefitted from the technical assistance they provided overall and were key to making this rewind successful.

Steve Jorritsma, Electric Motor Service Limited

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.