With HiFLEX services at Houghton International:

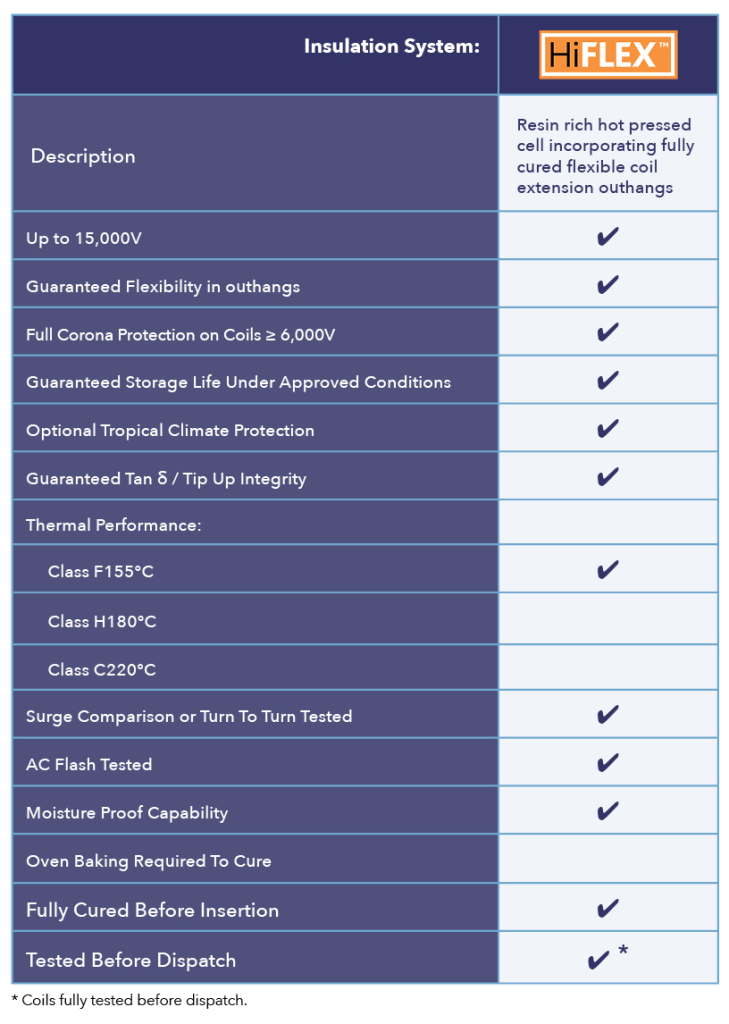

- Coils are fully tested at point of manufacture guaranteeing dielectric integrity.

- Coils can then be step-down tested before being inserted and throughout the repair process.

- Coils are fully cured but totally flexible in the end-winding (coil extension).

- Requires no baking after winding.

- Requires no VPI or impregnation.

- Guaranteed storage life — the coils are fully cured so they cannot change state in storage.

- Coils are supplied in a vacuum packed, moisture proof bag inside a heavy-duty wooden crate as standard.

- Class F 155°C as standard > 6.6kV.

- Allows total flexibility in its end-winding (coil extension), which can remain flexible for the machine’s cycle.

- Guaranteed flexibility of the coils, which is ideal for large two-pole windings, rewinding in situ and for skewed alternator coils.

- Only requires spray varnish to seal off outhangs.

Key Information

Further Information

Contact us for more information on our HiFLEX products and services

Get in touch using the boxes below and we’ll get back to you.