Houghton International conducted a full rewind and refurbishment on a large offshore motor with extensive flood damage.

The challenge

A 17 tonne, 4.6MW 3500HP DC thruster motor on an offshore rig had been severely damaged due to flooding. As a result, a complete repair and refurbishment to the stator, armature, bearings and brush gear was required.

The solution

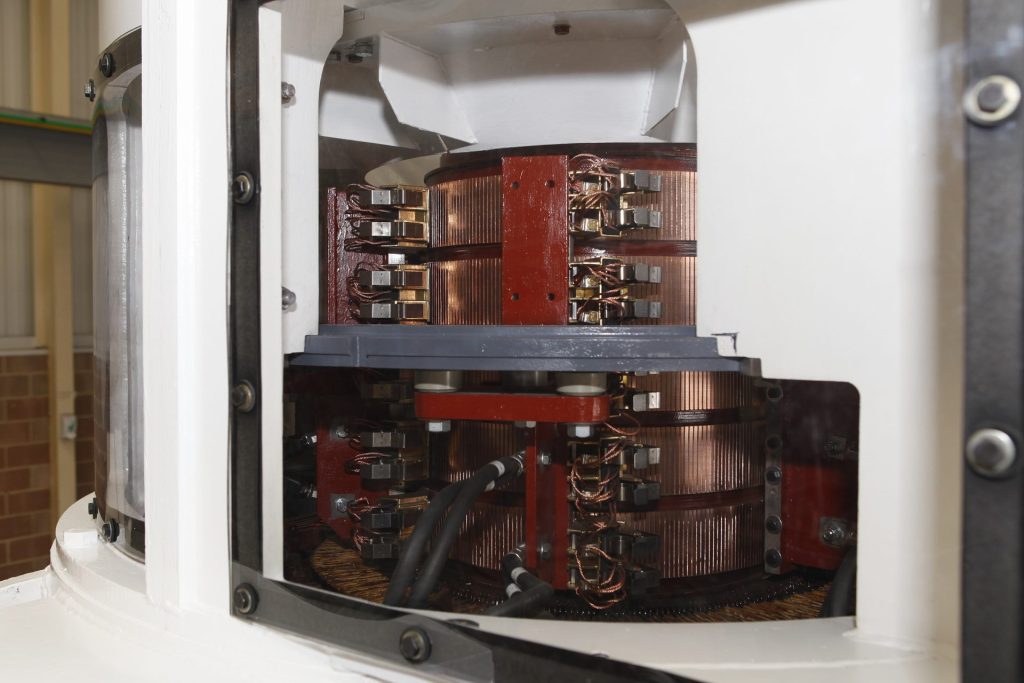

The motor was dismantled and all components completely removed leaving only the motor carcass. All components were individually tested to identify and diagnose faults. The final diagnosis highlighted a full rewind (stator and armature) and overhaul, including complete supply of new brushgear and supply of new bearings.

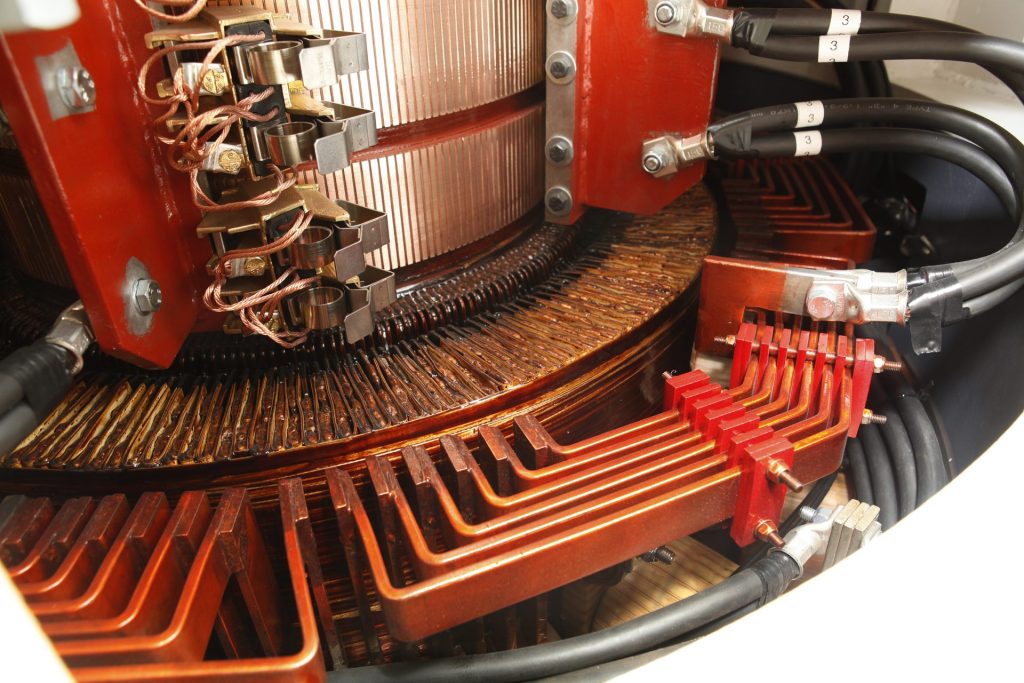

All windings were to be replaced, including armature windings, compensating bars, field and interpole coils and a new commutator. New coils and bars were manufactured, including edge wound interpole coils. The armature windings included dampener windings, equalizer windings and main windings, with all connections TIG welded to the new commutator. New field and interpole bricks were also manufactured.

Prior to re-assembly all components were shot blasted and painted with high specification marine paint. On completion the motor underwent a horizontal load test and vertical light run test.

Why Houghton International

Related Services

The Results

With our excellent in-house facilities including coil manufacturing capabilities, we were able to carry out all of this complex job at our facilities in Newcastle upon Tyne.

Regular progress reports were provided to the customer to keep them informed on the ongoing work and any changes to the initial project plan, as well as regular visits to our facilities to witness the works being carried out. As a result, the project was completed within the agreed budget and timescale.

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.