The challenge

A dock pump motor responsible for pumping water out of a dry dock in Leith had failed in situ. It was originally manufactured by W. H. Allen, Sons and Co Ltd in 1911 and therefore required the utmost care in removal from site and refurbishment at the workshop by a team with specialist experience. This difficult and complex life-extension job needed to be completed in the agreed timescale to minimise disruption to the customer.

The solution

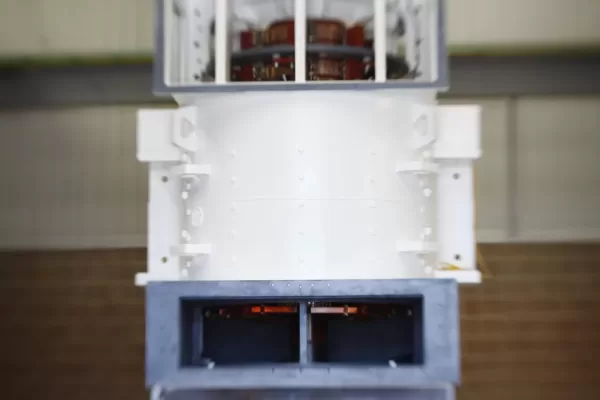

Two engineers were sent to site to carry out an initial inspection where they identified that the insulation was the cause of the failure. They removed the motor and then arranged for the dock pump motor and armature to be transported to Houghton International’s IECEx certified large machine shop. Upon a further assessment by the engineering team, the recommendation was to upgrade the insulation as this is where the initial failure lay and to re-use the original coils and connectors to minimise downtime and provide cost savings for the customer.

The work for the field frame consisted of removing the field coils and interpoles and stripping off the original insulation from the field coils and connections. Rather than rewind the field coils and interpoles, they were re-insulated with new insulation. The armature was steam cleaned and reinsulated using the VPI insulation system and the field and interpole coils were VPI varnished and refitted to the field frame. The commutator was also skimmed, undercut and balanced. Other works included a repair to the v-ring insulation, an overhaul to the brush gear and re-insulated brush gear connections.

Why Houghton International

Related Services

The Results

Full testing, including IR and drop testing, was conducted to ensure the pump motor and armature were functioning as expected before being returned to site, and a full warranty on all work carried out was provided. Once the dock pump was reinstalled and recommissioned by Houghton International’s experienced site services team, a follow up visit was scheduled to verify the operation.

The entire process was managed by Houghton International with the specialist team remaining in close contact with Dales Marine throughout the refurbishment. Transporting the assets to the workshop at Houghton International minimised any health and safety risks and the processes involved in the refurbishment was managed in a purpose-built environment.

Houghton International provided a professional service throughout and completed the refurbishment on time. Due to the age of the dock pump motor, this was a complex job and we were happy with the way Houghton International’s team of specialist engineers approached it from the onset. Bringing the equipment back to life has saved us time and money and I am confident that it will be in service for many more years to come.

Phil McFadyen, Dock Manager, Dales Marine

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.