Houghton International utilised their expertise in reverse engineering to carry out a full rewind of motor that was over 100 years old.

The challenge

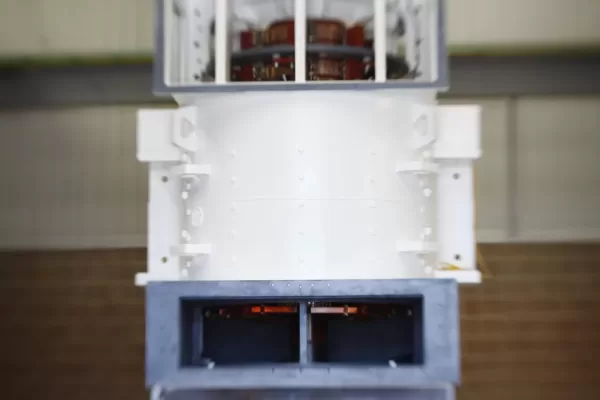

A dewatering pump, critical to the customer’s running of the shipyard, had been on fire in situ. At over 100 years old replacing the pump motor would have been impossible without significant cost or major operational changes, resulting in the motor requiring a rewind. In the absence of the original specification, the coils required reverse engineering. This complex job also needed to be completed within an agreed timescale in order to minimise downtime for the customer.

The solution

Houghton International’s expertise in reverse engineering was required for the rewind as hairpin coils, a non-standard type of coil, were used. Due to the age of the motor no direct replacement was available, so our engineering team used CAD software to redesign and optimise the coils for the motor rewind. Our in-house coil shop manufactured 21 groups of three hairpin coils and 336 rotor coils and subjected these to testing and quality assurance checks.

Previous experiences with Houghton International had given the customer confidence we could deliver on time and to the required standard. Updates and photographs were provided to A&P throughout the job to ensure progress was communicated clearly.

Full testing was conducted to ensure the motor was functioning as expected before being returned to site, and a fully warranty on all work carried out was provided. Once the motor was reinstalled on site, a follow up visit was scheduled to verify the operation.

Why Houghton International

Related Services

The Results

With all coils manufactured in house we were able to produce the relatively uncommon hairpin coils required for this job and have full control over the manufacturing processes, meaning we could guarantee the quality of the coils.

Following a full rewind, the motor was balanced and load tested before being returned to the customer, with a full warranty on all work carried out. A full test report was provided on completion of the job to verify the work carried out.

Our multiskilled team were utilised in order to achieve a quicker turnaround time as the motor was critical to A&P’s operations. As a result, the motor was repaired and returned to site ahead of schedule.

Houghton International provided a competitively priced offer and following an audit of their works and discussions, with both the management and operators who were to undertake the task, the order was placed with them.

“Throughout the process of overhaul and rewind A&P staff visited the Houghton International workshops and regular progress updates with photographs were provided by email. The repairs and rewind were carried out in a meticulous manner by the operatives who treated the motor as if it was their personal property.

“The motor was returned to site early and installed with the assistance of the A&P dockside cranes. Alignment and recommissioning were carried out by A&P and Houghton International working together. A subsequent visit was arranged following the motor having been “run in” to check the operation and alignment.

“Throughout the overhaul and rewind Houghton International have been a very professional company to deal with and have taken the care I would expect and is required on a motor of this size and age.

John Leckie, Asset Manager, A&P North East

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.