Houghton International’s experienced team of multi-skilled engineers carried out an overhaul of two diesel generators.

The challenge

Houghton International was awarded a three-year contract from Prosafe which included the planned maintenance and overhaul of two diesel generators from Safe Bristolia during docking. The job would require engineers from Houghton International’s site services team to travel to Norway to inspect, disconnect and arrange for the generators to be transported to Houghton International where the full overhaul would be undertaken.

The solution

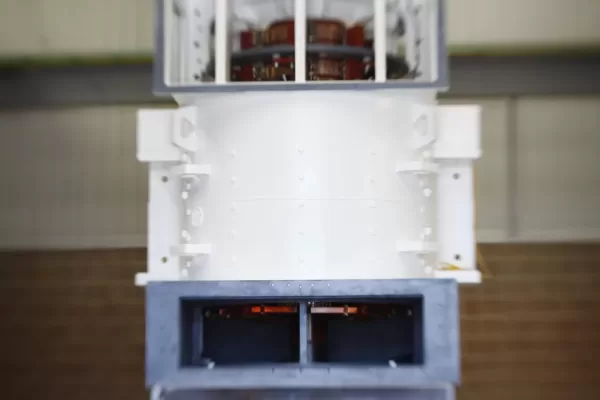

Houghton International’s electro mechanical services division have extensive experience in overhauls of this type and proposed a plan to project manage all aspects of the job including logistics. Two site service engineers travelled to the docked vessel in Norway where they electrically and mechanically disconnected both failed generators and arranged for the generators to be flighted off the vessel to be transported to the workshop at Houghton International. Once removed, it was evident that there was substantial shimming under the second generator. The engineers decided that the best scenario would be the supply a couple of complete shims various in thickness and assess this in more depth during the refit.

Upon arrival at the workshop, a full overhaul of each of the generator was carried out. After the final checks and testing were undertaken, the overhauled generators were then packaged and shipped back to the vessel in Norway where Houghton International’s engineers were on site to recommission and reinstall them. Both generators were inserted into their respective couplings and connected mechanically via flanged spigot on the belle housing.

Why Houghton International

Related Services

The Results

The entire process was managed by Houghton International with the team remaining in close contact with Prosafe throughout the overhaul. Transporting both generators to the workshop at Houghton International minimised any health and safety risks and the processes involved in the overhaul was managed in a purpose-built environment. Once reconnected on Safe Bristolia, both generators were test run and found to be operating as expected.

I have used Houghton International for a number of years since having been recommended by another electrical subcontractor. In this time, we have used their services to inspect and overhaul a number of large DC traction motors, smaller AC fan motors and most recently clean and service the vessels main alternators. During these projects I have found their service efficient and reliable as well as offering cost effective solutions to vessel specific issues involving motors and alternators. At this time, I look forward to working with Houghton International in the future at both their workshop facility and onboard our vessels.

Richard Younger, Vessel Manager – Chief Engineer

2

engineers on site

2043 kVA

generator inspected and overhauled

588

accommodation capacity of the Safe Bristolia

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.