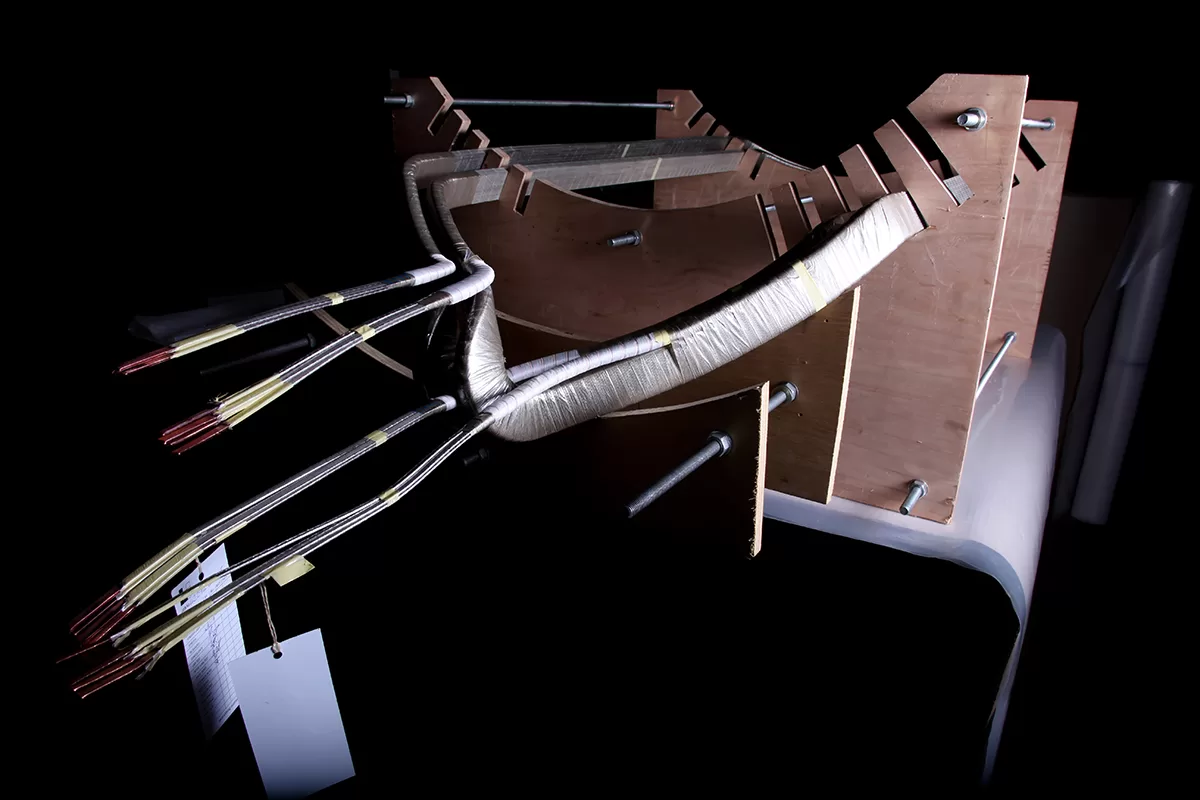

Houghton International supplies a range of high voltage coils specifically designed for the repair market, including HiFLEX – our fully cured, fully tested, totally flexible insulation system for improved fit, quicker installation and reduced risk of damage.

Experts in winding and high voltage coil manufacture with over 35 years of experience, we know what to look out for and some of the common mistakes that are made when specifying, winding and testing coils.

Based on our own experience and our experience of working with other repair shops globally, we have developed a range of ‘How to…’ guides to support our customers in the critical elements of the process.

The first in the series of guides is ‘How to record accurate coil data.’ When placing an order for HV coils, in order to ensure accurate fit and specification it is critical to ensure that key data points are measured correctly. Badly fitting coils are not only difficult to wind, but may also result in added downtime, poor cooling, partial discharge or electrical failure. Our intention is to work with customers to ensure a trouble-free customer winding experience – which starts with the coils.

Developed to be used alongside our coil data sheet, the guide is useful for both experienced winders and those new to the task to ensure consistent and accurate data can be supplied. Our experienced engineers can also talk you through the guide in more detail in with one-on-one training or group sessions for your winding department as needed.