The challenge

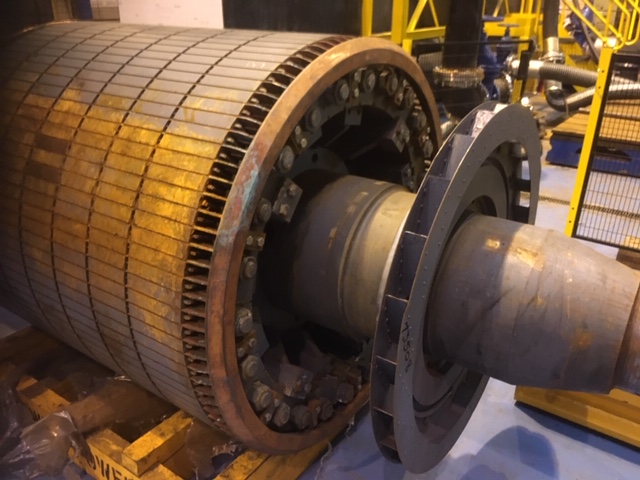

Houghton International was awarded an order for a refurbishment of a large rotor from RWE Generation UK, the UK’s second largest producer of electricity generating more than 10 percent of British electricity. To be used in a 3.3kV circulating water (CW) pump motor, the rotor was a spare that was originally stored in a container that had accidently been submerged in water. Due to this, the condition of the rotor had significantly deteriorated over time.

The solution

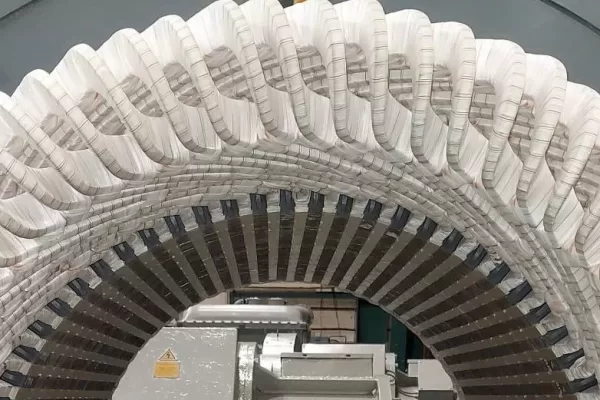

After collecting the rotor from the Aberthaw power plant in Wales and transporting it to Houghton International’s IECEx certified large machine shop, an initial inspection and assessment on the condition of the rotor was carried out. Based on the findings and the fact that the rotor was in poor condition as a result of being submerged in water, Houghton International recommended that a full refurbishment was carried out.

The refurbishment consisted of removing and inspecting the bearings, carrying out datum checks, steam cleaning and stoving the rotor. Following that, the engineering team carried out an inspection of the rotor bars to check for any cracks. Additionally, a new fan blade arrangement and fan hub were manufactured and installed onto the rotor. The rotor was then dynamically balanced to ISO grade 2.5 and then sprayed with anti-tracking varnish. The rotor was then fully quality assurance checked and made ready for delivery back to customer’s site to be reinstalled.

Why Houghton International

Related Services

The Results

The job was project managed from start to finish by Houghton International, including the collection of the rotor, inspection and refurbishment of the rotor and transportation back to the Aberthaw power plant.

The work was completed within the timeframe requested by the customer and regular updates were provided, keeping RWE Generation UK informed throughout the process. Houghton International ensured that the job was cost effective for the customer by agreeing the scope of work in advance of work commencing.

Following the refurbishment of the rotor, full quality assurance checks and testing were undertaken before being returned to the customer, with a full warranty on all work carried out provided. A full test report was provided on completion of the job to verify the work carried out and provide assurance to engineers on site.

Overall, the team at Houghton International demonstrated professionalism throughout the job. There was exceptional communication throughout, providing us up to date information of progress. The level of work carried out was to an excellent standard and delivery of the rotor back to site was done in a timely manner.

Michael Chandler, RWE Generation UK

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.