The challenge

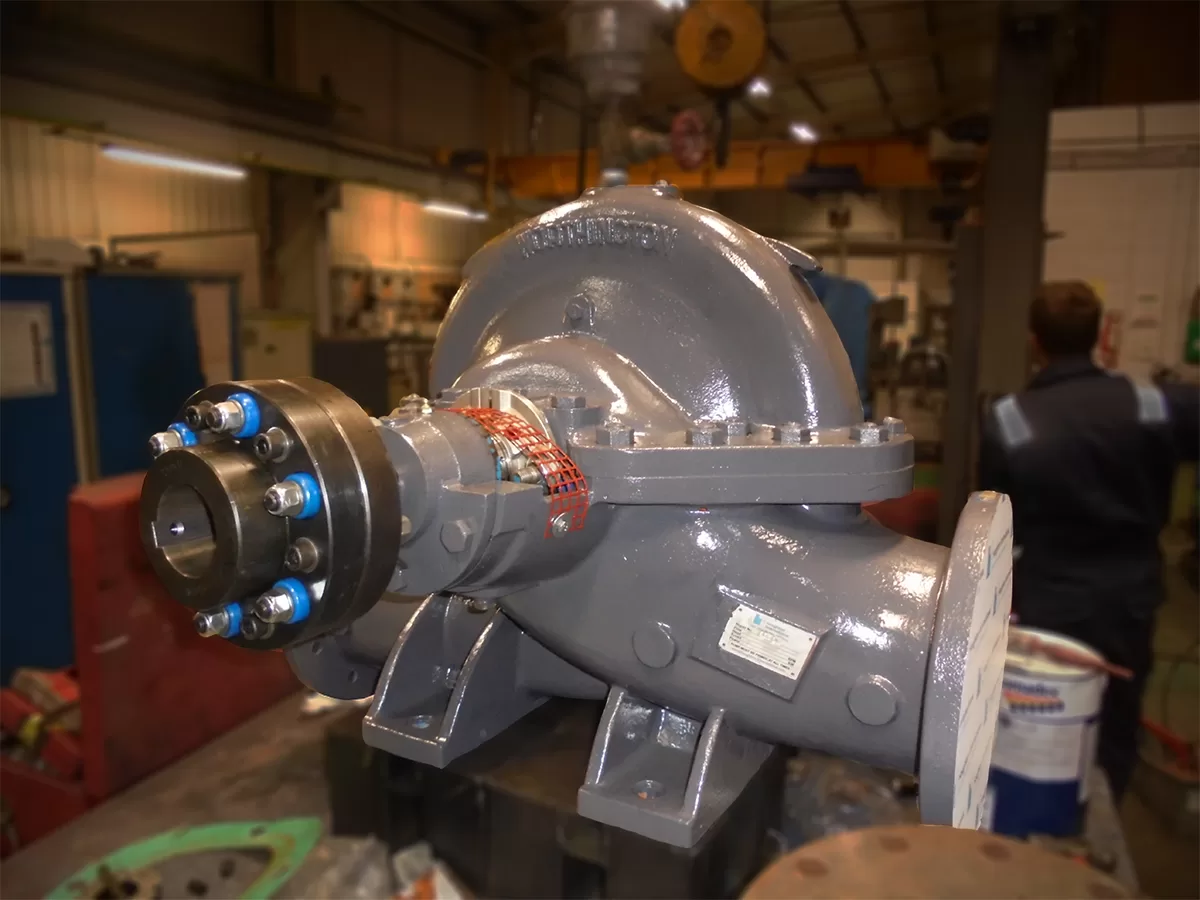

A Worthington Simpson split case water pump from a cooling tower was running inefficiently and the customer was considering options to replace the pump. However this would have required modifications to the existing pipework to enable a new pump to be fitted, further increasing the costs to the customer.

Houghton International proposed to overhaul and upgrade the ageing pump, improving its efficiency, reducing running costs and extending its working life.

The solution

The customer had reported that the pump was overperforming, consuming more power than was necessary for its intended usage. After the pump was stripped down and cleaned, the impeller was trimmed to reduce power usage and bring it in line with the duty required, helping to improve the pump’s energy efficiency.

A specialist coating was then applied to the pump, creating a low friction surface to further improve efficiency. The pump underwent a full overhaul, including replacement of bearings and impeller rings. The pump was upgraded from gland packing to mechanical seals to save power, increase durability and reduce the chance of leakage.

Before being returned to the customer, the rotating element was balanced to G2.5 and the pump reassembled and tested in our on site pump testing facility.

Why Houghton International

Related Services

The Results

As a result of the work carried out the 30 year old pump was brought up to date. This meant the customer no longer needed to replace the pump, resulting in significant savings.

Application of the specialist coating increased the efficiency of the pump by 3-5%. It also helped extend the lifespan of the pump by protecting against corrosion and erosion. As a result of the work done, the pump was able to operate at the required duty whilst reducing the power consumption by 8-10%. This reduced the energy required to run the pump, reducing running costs by around £5,500 per year.

Houghton International provided us with significant savings over replacing the pump with new by refurbishing and upgrading our existing Worthington Simpson split case pump. I’m so pleased with the work done by the team that I have already recommended Houghton International to several others.

We had expected to have to replace the pump, but the modifications made have enabled us to run our existing pump more economically, which has both cost and environmental benefits. Thanks to the team at Houghton International we can continue running the pump for well into the foreseeable future.

Tony Husthwaite, Energy, Engineering Support and Site Services Manager, Renolit

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.