The challenge

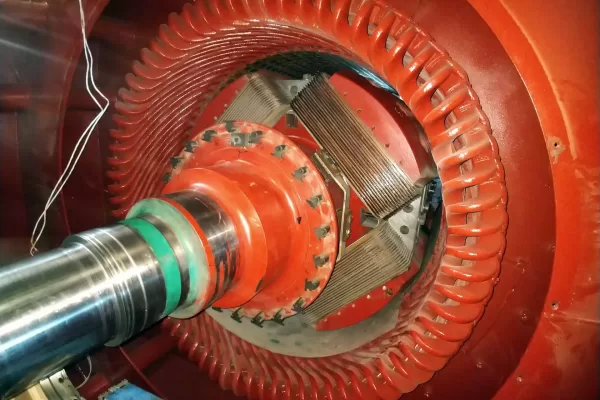

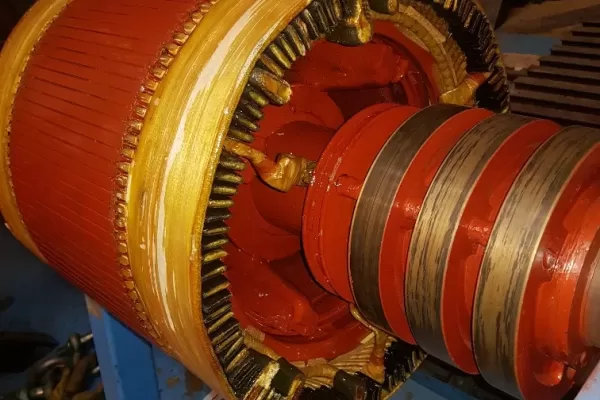

Houghton International was awarded an order from Equipo de Pruebas to manufacture and supply 60 (+2 spare) high voltage stator coils. This was the first ever job from a customer in Mexico. The coils were for a 2600kW, 4-pole motor operating in an environment with high humidity.

The solution

The customer found out about Houghton International online and initially requested a quote for the HiBRID insulation system. However, after further dialog with the customer to understand their needs, it was apparent that this system would not be suitable. This is because once HiBRID coils are wound, the stator would need to undergo Vacuum Pressure Impregnation (VPI) but the customer did not possess any VPI facilities.

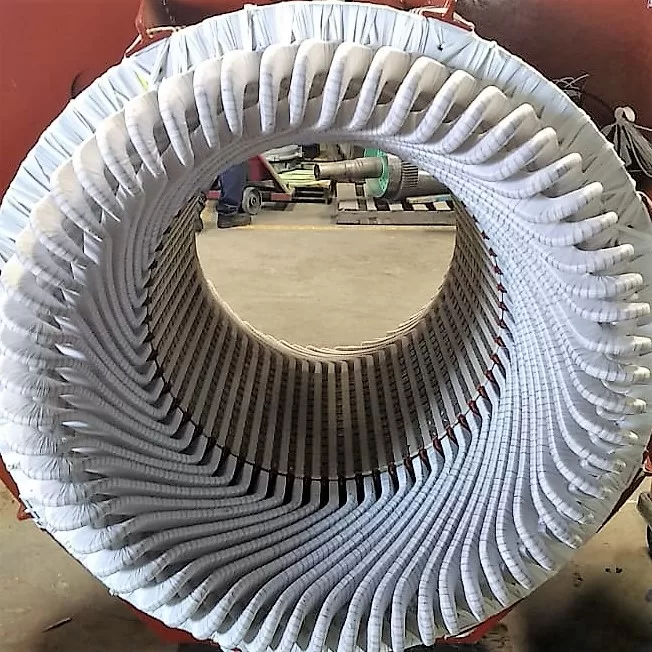

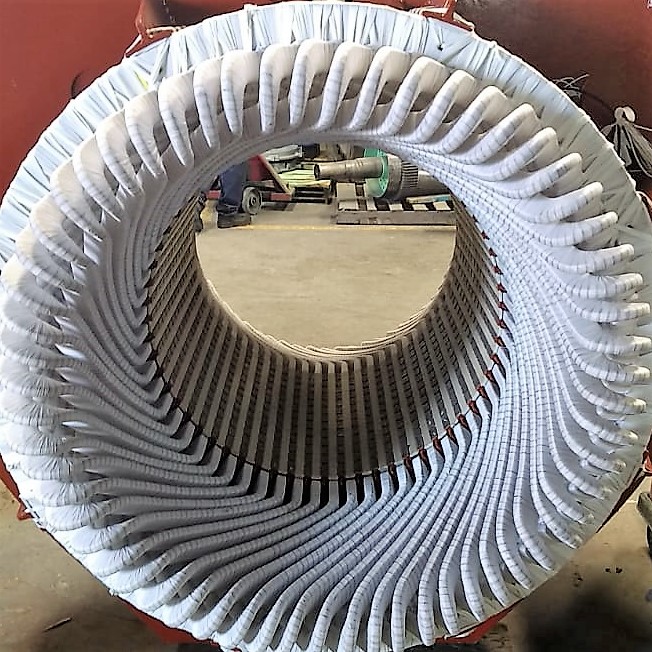

Based on the application and the customer’s capabilities, Houghton International recommended its unique HiFLEX system as this insulation system is fully cured and therefore requires no baking/varnish or impregnation. It is fully tested guaranteeing dielectric integrity and totally flexible in the end winding (coil extension).

It was also suggested to the customer that when manufacturing the coils, a tropical seal system should be applied as this is an ideal solution for use in high humidity areas such as Mexico. Applying a moisture resistance tape, Epoflex, protects against moisture, mechanical load, damage, resin flow, and atmospheric pollutants. The shrinking characteristics and mechanical toughness of Epoflex tapes are purposely designed for these high humidity applications. Finally, an epoxy varnish coating layer is applied to the outhangs, sealing it further from any external moisture and chemicals.

With the customer taking the suggestions on board, Houghton International manufactured and supplied all 60 (+2 spare) 13.8kV diamond coils utilising the HiFLEX insulation system.

Why Houghton International

Related Services

The Results

The HiFLEX fully cured and fully flexible insulation system gives improved fit, easier install and reduces the risk of damage to the coils during installation.

All coils were tan delta, Hi-pot and interturn tested to British Standard specification (BS EN 5029 1999) with full quality assurance checks conducted at each stage of the manufacturing process and individually quality assurance checked prior to dispatch.

The coils were also supplied with an auxiliary winding kit to guarantee an easier completion of the rewind process for the customer. All coils were delivered in a foil vacuum sealed bag system, inside a moisture proof wooden crate ensuring that they are not damaged throughout their expedited transit to Mexico.

We came across Houghton International online and submitted an enquiry to them via their website to which they promptly got back in touch with us. On the whole, we are extremely happy with the service received throughout the project and the exceptional quality of the coils they produced. We were particularly impressed with HiFLEX system that they recommended to us and very pleased about the application of epoxy resin to protect and seal the coil heads from dust and moisture. This is our first experience with Houghton International and we would not hesitate to use them again in the future.

Pedro Farreras, Equipo de Pruebas

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.