The challenge

Electromotores provide servicing of rotating electrical machines to a number of sectors in Central and South America and the Caribbean areas.

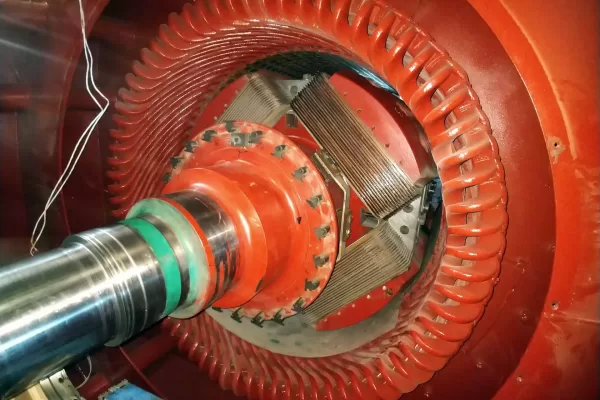

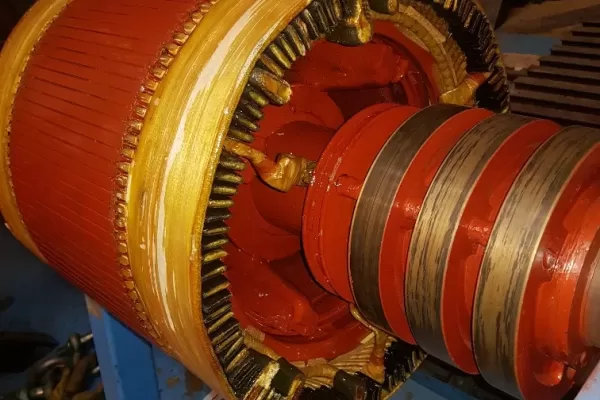

An 11,200kW machine at Elcosa Power Station in Honduras had suffered a failure to main stator windings and was sent back to Electromotores workshop where data was recorded. Electromotores asked us to manufacture a set of 126 + 2 spare 13.8kV coils. The coils had to be produced as quickly as possible to minimise downtime at the power station.

The solution

We reverse engineered a new coil design using data provided by Electromotores to offer maximum life extension of the refurbished machine. HiFLEX coils were chosen for the project as they allowed moisture proofing to be applied, fully tropically sealing the system. As the coils were to be operating in a humid environment with the potential for contamination from air pollutants, adding this insulation system helps to protect the coils and improve their lifespan.

Houghton International’s patented HiFLEX coils use a world-leading, fully cured, totally flexible insulation system. Using HiFLEX coils enabled further testing to be carried out during the rewind process to ensure installation has been properly carried out and the coils will operate as expected once the rewind is complete.

Before dispatch, the coils were Quality Assurance checked and subject to our standard testing schedule, including Hi-Pot testing at 34.32kV and interturn/surge testing at 28.6kV, to measure the dielectric integrity and insulation of the coils.

Why Houghton International

Related Services

The Results

The coils were fully sealed with our tropical seal system to provide protection in the humid conditions they would be operating in. Preventing contamination from air pollutants helps extend the life of the coils, increasing the time between machine rewinds. All coils underwent full dielectric testing and quality assurance checks at our facility prior to dispatch.

Our HiFLEX coils are flexible for easier installation, especially in the case of larger machines, and are supplied with a winding kit to ensure the customer has everything they need to complete the rewind process to a high standard.

The coils were dispatched to Electromotores by the fastest ship freight option available. Thanks to our excellent relationships with a range of international freight forwarders, we are able to ship coils time and cost effectively.

I can say that I recommend, and actually I have recommended Houghton in the past. We always receive very good customer service, including the time to get response for both quotations and technical inquiries. I give you special thanks regarding to this aspect.

The coils and related products are of very good quality. We know that good materials and an efficient manufacture control are employed, so, the final product that we receive matches and exceeds the technical requirements requested.

Additionally, I would mention the kindness and charisma of the personnel at Houghton, that allows trust and good relationships.

Rolando Rodriguez, Electromotores

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.