Houghton International carried out a complex overhaul of a 37 tonne generator at its large machine shop facility.

The challenge

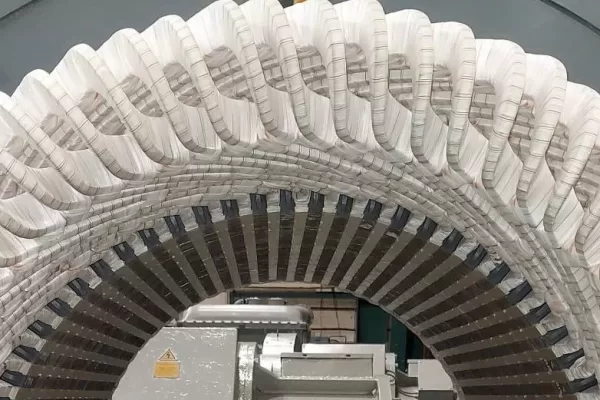

Inspections of a 24 MVA Steam Turbine Generator at the RWE Conoco Phillips site had revealed movement in some of the salient pole rotor insulation packers. This led RWE to start a tender process for suppliers to submit a price to un slot the Rotor in situ and carry out works to replace these insulation packers.

Limited space on site would have made it difficult to complete the job safely in situ but removing the 37 tonne generator from the facility would also be a significantly difficult procedure. The rotor had never been removed from the stator since commissioning and the generator was not designed to be removed from the site.

The solution

During the tender process, Houghton International was the only business whose tender proposed the removal of the generator from site. The decision was made to avoid compromising the quality of work and to minimise health and safety risks.

Houghton International laid out a plan to project manage every aspect of this process, including removal of the generator from site and transportation to and from the workshop. As a result, RWE opted for the generator to be taken to Houghton International’s facility rather than attempting the repairs in situ.

The process involved the safe removal of a section of the facility’s roof with a 200 tonne crane in order to carry out a direct lift on the generator. As this was a CDM site safety was paramount, so our site team worked closely with the safety inspectors on site to ensure we complied with all policies and procedures.

The generator was transported to our specialist large machines site in Newcastle upon Tyne to be dismantled before the rotor was unthreaded from the stator for inspection, testing and repair. The insulation packers were replaced and the generator was fully overhauled.

Further checks and testing were conducted during reassembly before transporting the generator back to the RWE site. Once the generator has been lifted back into place, it underwent laser alignment and a series of adjustments were performed until the correct reading was achieved.

Why Houghton International

Further information

Related Services

The Results

A turnkey solution was offered with the whole project managed from start to finish by Houghton International, including the removal of the roof, transportation and the reinstallation of the generator once the work had been carried out.

The choice to transport the generator to the Houghton International facility minimised health and safety risks and meant that all work, including the process of unthreading of the rotor from the stator which required a high level of precision, could be conducted in a well-equipped, purpose-built environment.

The Houghton International team remained in close contact with RWE staff throughout the repair, providing regular reports on progress, testing and any additional repair work to be carried out.

Houghton International were awarded the contract following a detailed tendering process to carry out the removal, repair and replacement of a 24MVA Generator. Overall the level of work that was carried out was exceptional and professional.

The communication levels were found to be excellent before work commenced and throughout the project. Through this Houghton International were able to maintain in providing up to date information of progress. This in turn enabled a more collaborative approach between the two parties and was therefore reflected in the success the work that was completed to time, to budget and to the right quality standard.

Senan Haddad, Electrical, Control and Instrumentation Engineer, RWE

37 tonne

weight of the generator

24 MVA

power of generator

37 miles

distance generator transported to Houghton International

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.