Implementation

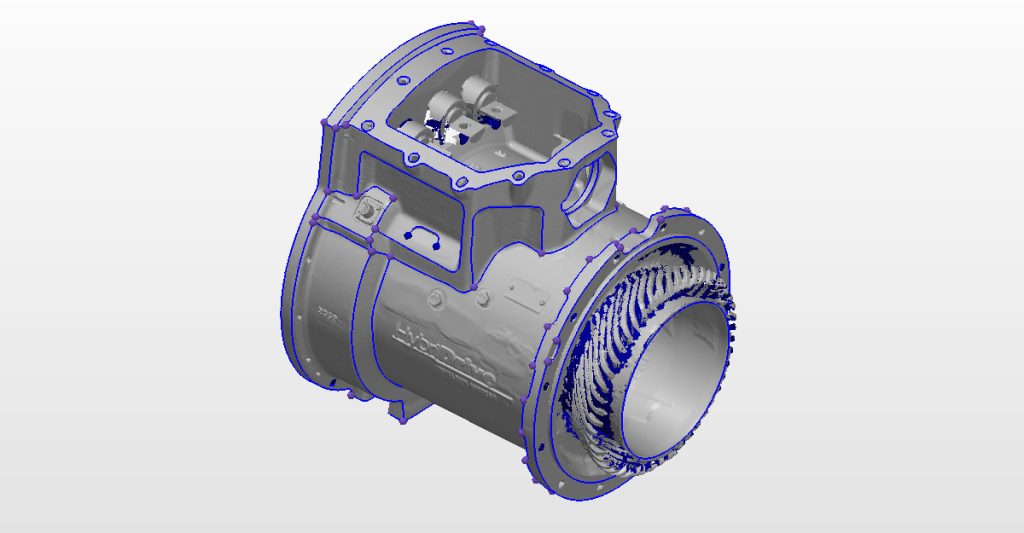

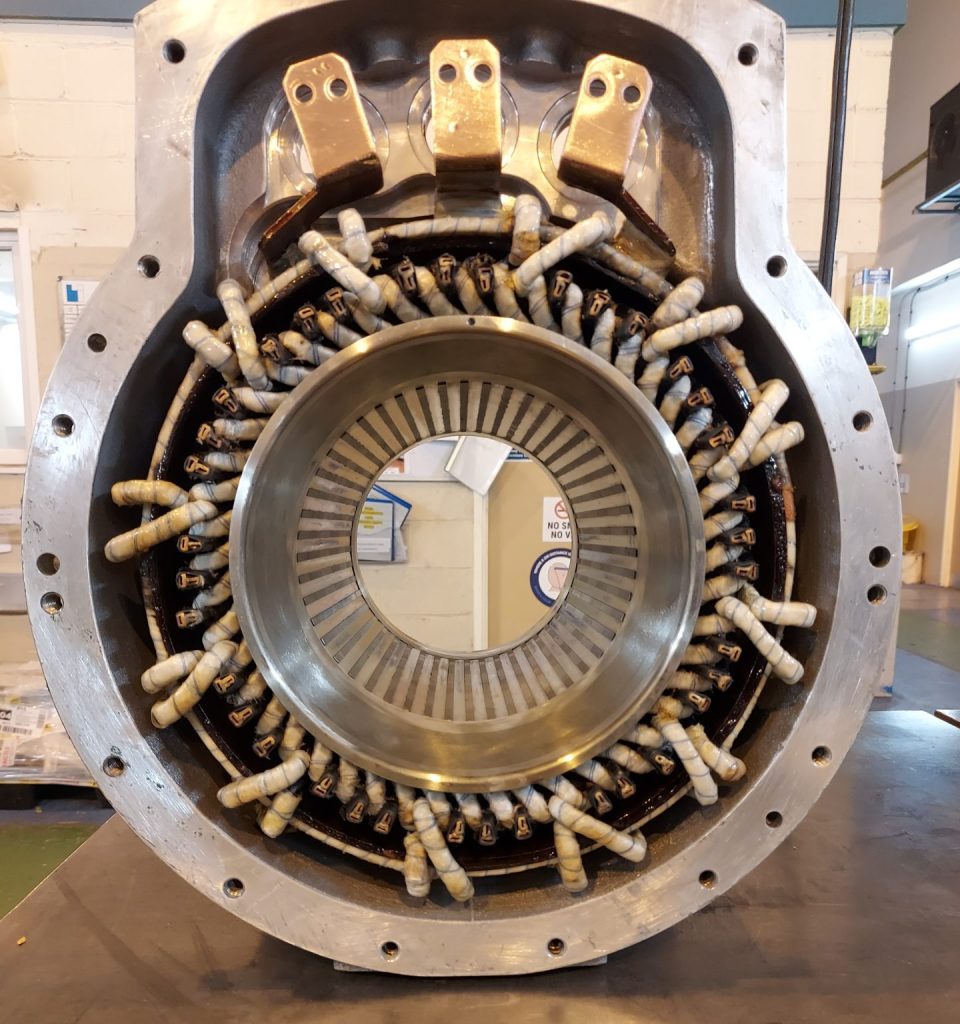

A 3D CAD model of the motor was produced to provide a detailed working specification. Initial inspections revealed the motor required a rewind. The coils were reverse engineered and manufactured in-house. An unusual style of Hollow Copper, designed to run coolant through the, windings was used in the motor coils. Specialist tooling was manufactured to ensure optimum coil fit and windability for a high quality rewind.

Overhaul

The units were tested, including pressure testing to identify any potential coolant or oil leaks, these tests were in line with the operating company and Transport for London’s requirements giving the customer added peace of mind before the motor was returned to service. All steps of the repair process were documented to provide a detailed working specification and reported back to the operating company.

Outcome

The operator was provided with a cost, time efficient and sustainable alternative to sourcing new motors when existing ones fail, significantly reducing lead times and avoiding reliance on OEM’s, all at a reduced cost compared to buying a new replacement. Houghton International is experienced in the delivery of both volume contracts and ad-hoc casualty repairs and are able to mobilise quickly to carry out emergency repairs.

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.