Implementation

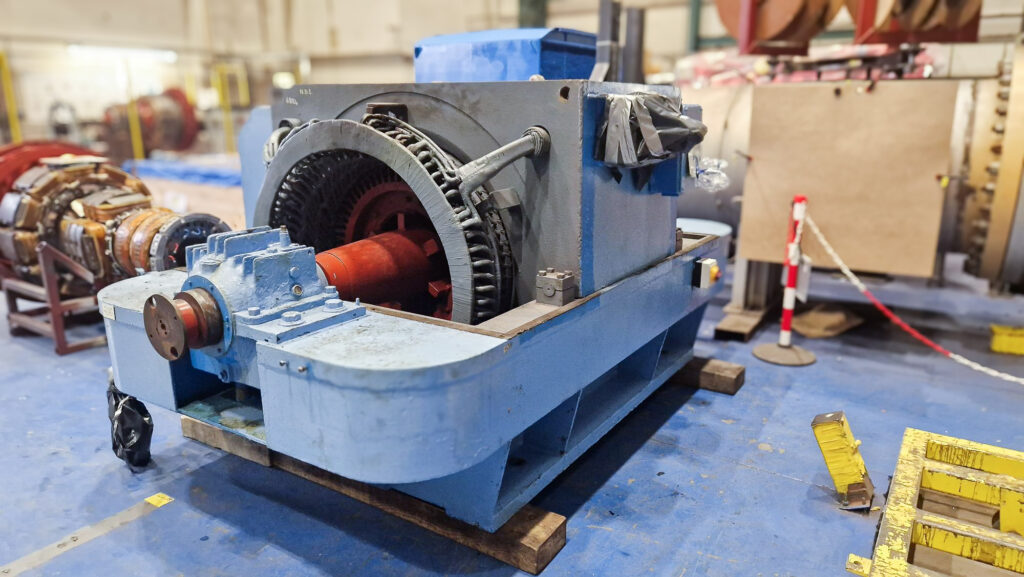

We removed the AC traction motor safely and conducted a detailed assessment of its condition. The inspection revealed that the coils had sustained significant damage, therefore a complete overhaul and rewind was required.

Overhaul

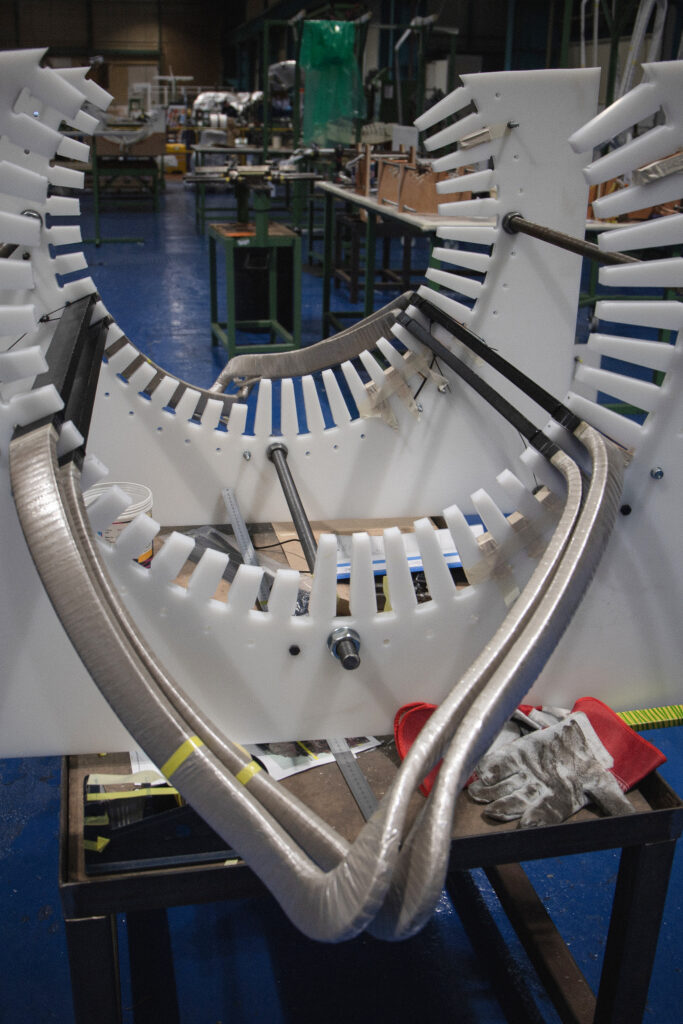

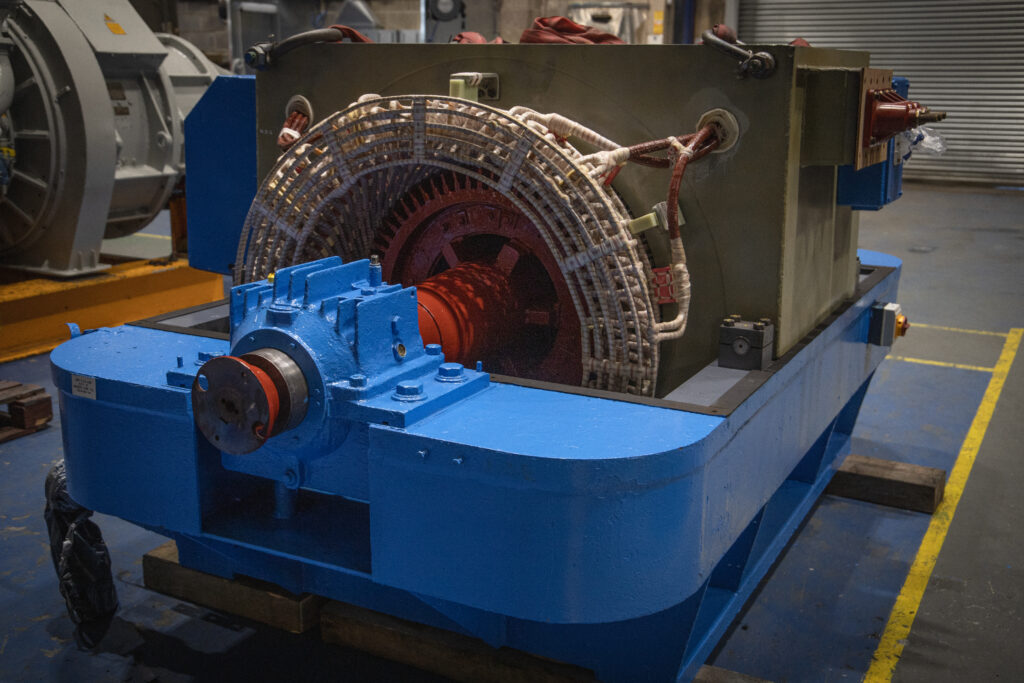

Due to the age of the AC motor it required a complete refurbishment, including an armature rewind, requiring the creation of new HiFlex coils and employing the VPI process to preserve the current commutator, a new stator and fresh paint.

Outcome

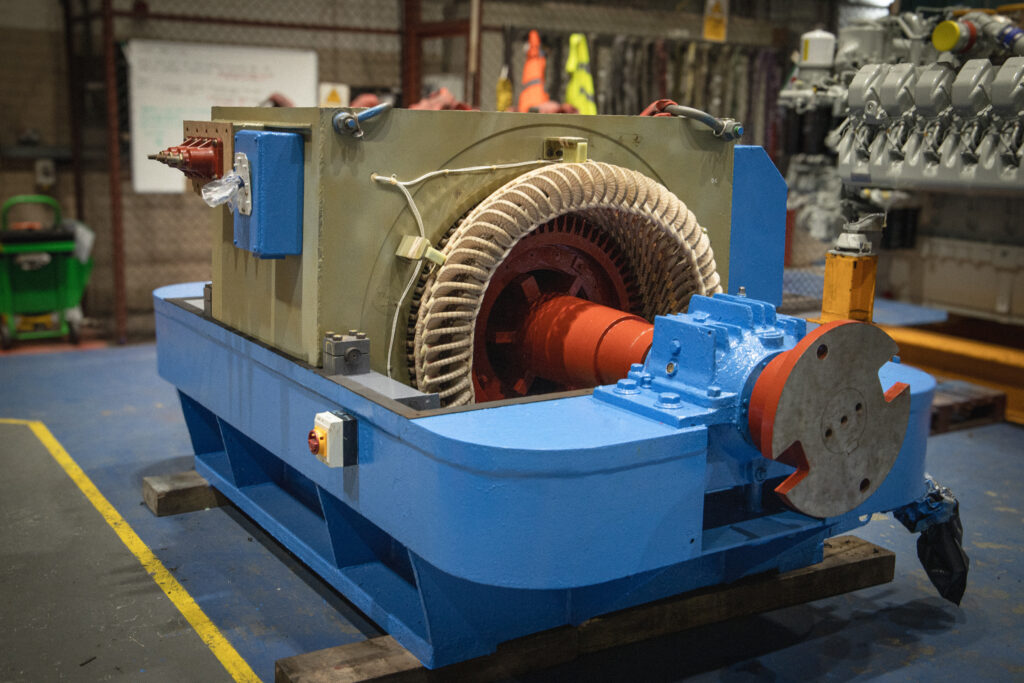

Each operational component underwent a thorough cleaning while defective parts were repaired and the bearings replaced. The AC motor was reassembled and given a fresh coat of paint for a polished finish before being returned to the customer.

We have up to 158 checks and tests for AC Motors throughout the repair process. After our initial inspection, we performed static tests on field and armature windings against specification requirements. We finish with a final Quality Assurance test to ensure the coil’s stator condition meets our specifications.

Prior to Repair

The Restoration Process

Future Proofing Assets, Even in Emergencies

24 Hour Emergency Repair

We minimise customer downtime by operating a 24-hour emergency repair service that is operational 365 days a year. Our engineers specialise in electro mechanical assets offering swift, bespoke solutions to minimise downtime and restore functionality of critical assets.