Implementation

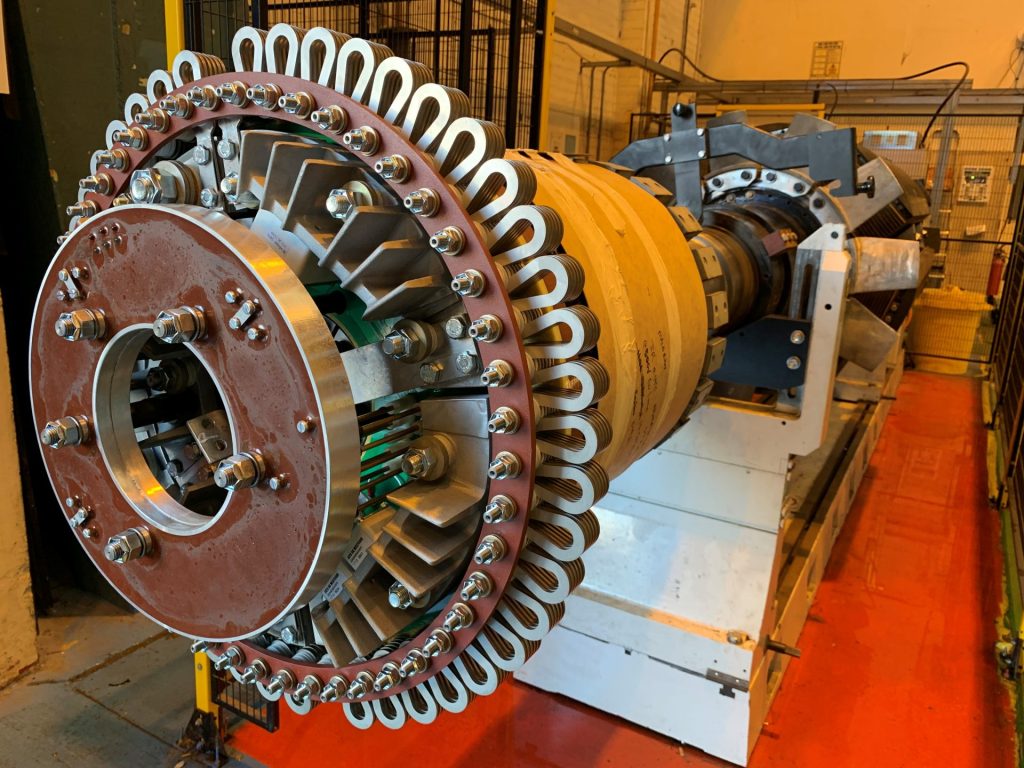

A dedicated clean room area was erected to prevent any contamination of the stator and windings. The primary scope of the works consisted of refurbishment of the stator of rotor. Stator windings were stripped out under controlled conditions to prevent any possible damage to the stator core and an assessment was carried out to increase the amount of copper in the stator windings and improve the efficiency of the motor.

Overhaul

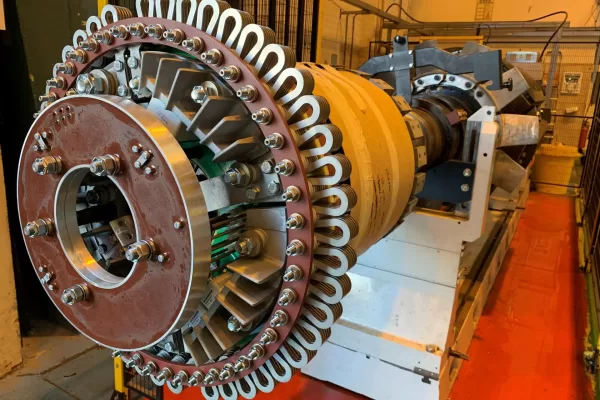

Existing blocking, bracing, slot wedges and coils were carefully removed to avoid damaging the slots and laminations, followed by cleaning of the stator core in preparation of the new windings. A core flux test then followed to determine the conditions of the core. 72 HiFlex Coils, manufactured in-house were wound by a specialist winding team, each industrial coil is fully tested at the point of manufacture guaranteeing dielectric integrity.

Outcome

Coil connections were remade for the rotor, six new up-shaft leads were manufactured and new insulators and up-shaft bars were fitted and secured. A new Rosenberry hub was also fitted. IR tests were carried out on the refurbished motor, it was fitted into the rewound stator followed by assembly of the bearings, covers and components and painted. The motor was then despatched to the customer ready for reinstallation and recommissioning.

Houghton International was awarded the order following a tender process to carry out a refurbishment of a 7750 kW synchronous motor. This motor is a critical asset at our Fawley plant, and it was imperative that the job was carried out to the highest standards.

On the whole, I am extremely pleased with the quality of the refurbishment and the competence shown by the team at Houghton International. The communication from the very beginning was excellent and this gave us that added confidence in the team working on the motor.

I would not hesitate to recommend Houghton International and would gladly work with them again in the future.

Steve Wilson, Electrical Engineer, BOC Fawley

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.