Implementation

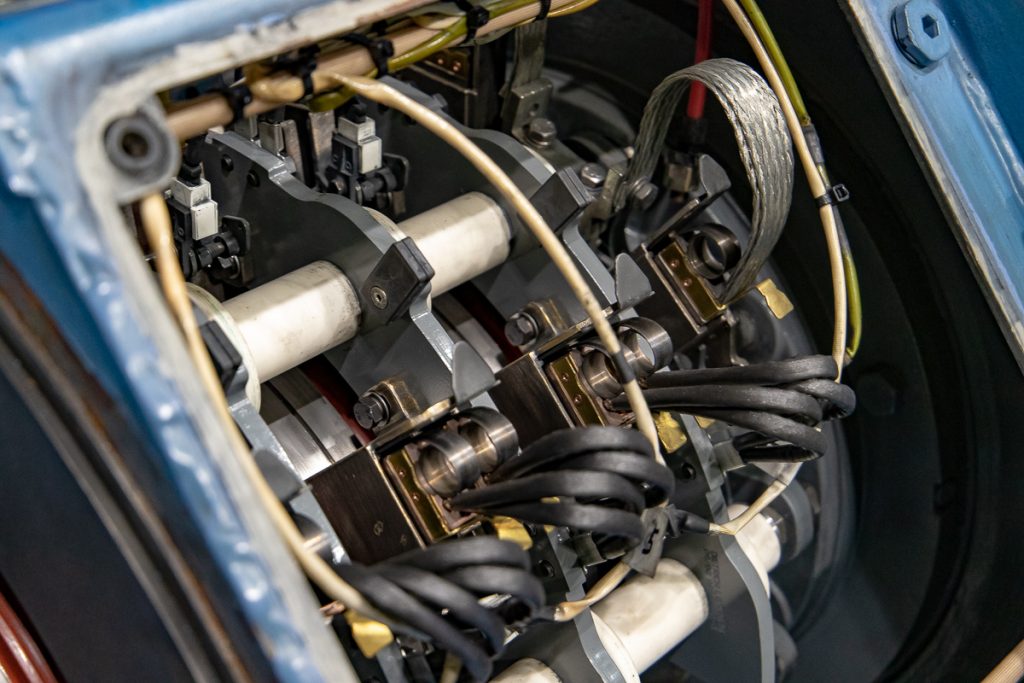

The generator was dismantled and tested on-site at Houghton International. A detailed inspection of the internal parts with a full range of Baker tests, including, insulation resistance, coil resistance, HiPot, interim surge and polarisation index testiing to identify any signs that could indicate issues within the stator windings. Visual observations identified several observations to be addressed.

Overhaul

A high level of carbon deposits were found in the brush gear slip ring enclosure and excessive carbon debris had also caused an ingress of carbon particles into the stator windings. Our engineers recommended that this issue be monitored. As this pattern of wear could result in a premature breakdown of the coil insulation we also recommended that the brushes were monitored which were showing signs of uneven wear.

Outcome

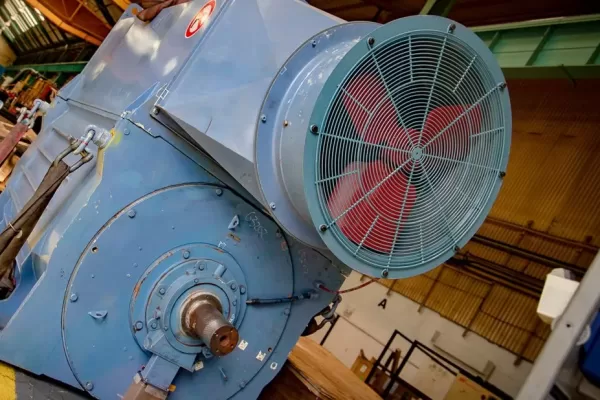

The cooler fan motors were overhauled including replacement of the brushes, bearings and brush gear. We also recommended a brush gear maintenance plan to included full removal of all of the brushes and a periodic deep clean of the inner brush gear enclosure. The stator was revarnished to protect the worn areas of the wedges by recoating the porous areas. The generator was reassembled, retested and despatched back to the customer.

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.