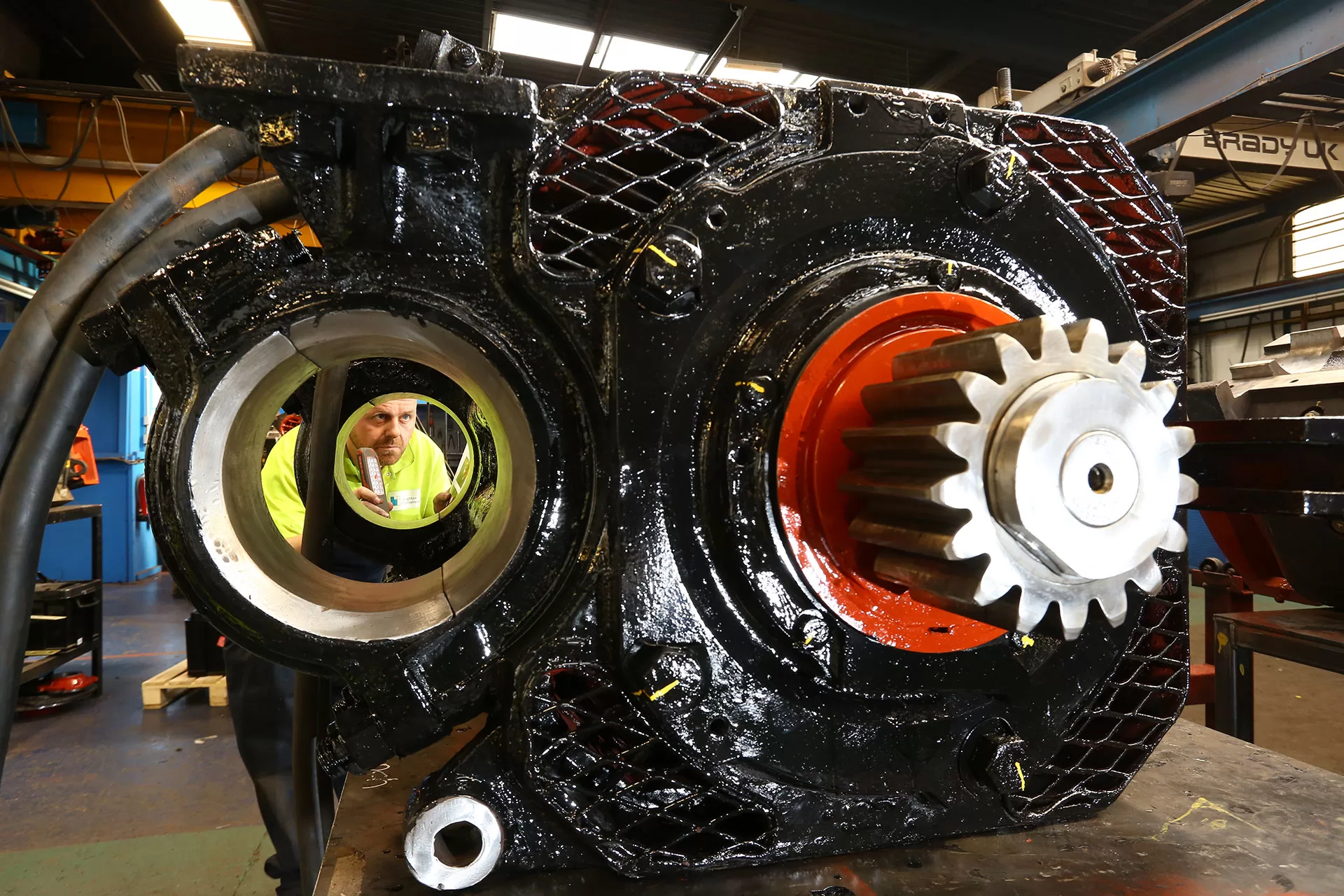

Houghton International’s RISAS-approved facility specialises in the repair, maintenance and life extension of electro mechanical assets into the UK and global markets, including AC and DC motor repairs.

Offering a broad scope of repair and overhaul services for AC/DC traction motors, our cradle to grave OEM manufacturing and life cycle management service provides the entire range of original motors to the OEM’s specification, with options to provide life-cycle or in-warranty service and maintenance.

We have the capability to rewind and vacuum pressure impregnate (VPI) both epoxy and silicone resins and our AC motor test rig can dynamically test all AC railway traction motor specifications. Utilising rotor bar crack detection equipment and automated TIG welding and undercutting equipment our quality processes are second to none. Furthermore, all traction coils are manufactured and tested in house, in our dedicated coil facility, to ensure full control over quality and delivery.

Our pioneering HiTRAX™ life extending insulation system was specifically designed for use in the rail industry, addressing the unique conditions of moisture ingress and significant temperature variation that contribute to the deterioration of a traction motors dielectric integrity. Units running with our HiTRAX insulation solution have been running without a single failure across the UK rail system for almost 17 years.

Our aftermarket service is focused on train operators, owners, bogey overhaulers and OEM’s requiring scheduled maintenance, casualty support and in-depot condition monitoring.

Our capabilities include:

- VPI facilities: 2 x individual plants processing: Epoxy (Ultimeg 2002) and Silicone (Wacker H62) resins allowing 160°C Class F – 220°C Class C resin impregnation

- HiTRAX™ insulation system proven over 15 years for both epoxy and silicone systems. The ideal life extension solution providing cutting edge composite insulation technology to maximise life cycle

- 2 x Schenck balancing machines

- In-house coil manufacturing facilities

- CAD function

- Dynamic rotor bar crack detection

- Induction brazing facilities

- Load testing facility and capability

- Winding and insulation system redesign services

As specialists, we have invested in industry-leading technologies and patented solutions for the Rail industry, working with clients to eliminate failures, improve reliability, increase lifespans, and significantly reduce cost of refurbishment and/or the need to replace existing units.

We work with customers in the rail industry to solve complex engineering problems, our experienced engineers and research and development department work closely with the rail industry to develop innovative solutions to challenges faced, such as snow ingress or detreating insulations systems. Further to this, we also utilise our links with trade associations and academic links to develop new intellectual property rights for commercial implementation. For example, we worked with Porterbrook in the UK as life extension consultants for their 458 fleet Juniper AC traction motors in conjunction with Newcastle University.

We understand that for our clients, traction motors can be at the heart of service costs, reliability and commercial performance of each service and our focus is aligned totally to these wider service and business objectives.

Contact us today to learn more about our traction motor services, or our other services including electric motor repairs, and electric motor rewind services.

Contact us for more information on our AC and DC traction motors services

Get in touch using the boxes below and we’ll get back to you.