Specialist electro mechanical engineering support

Based on our own experience and requirements we offer specialist electro mechanical engineering support. Our skilled and knowledgeable team have worked on a wide range of machines globally and can provide training and support in relation to taking motor data, specifying the most appropriate insulation services and improving/ upgrading the performance of machines.

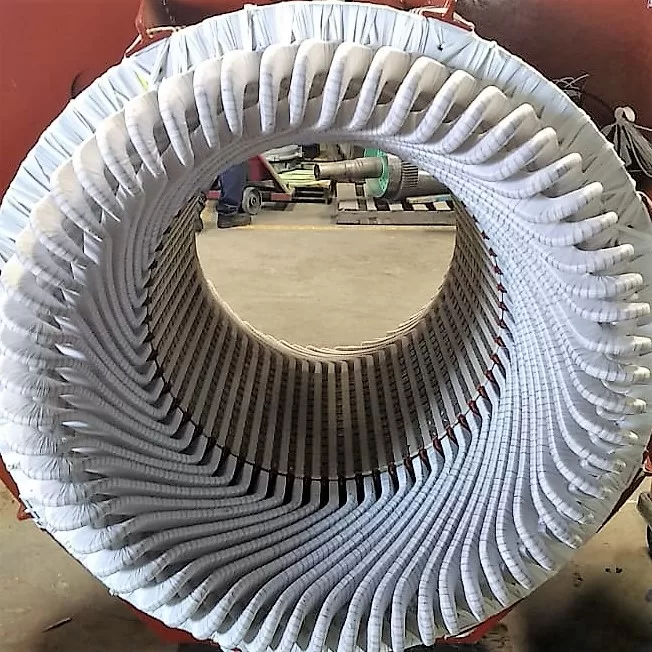

Our engineers are also skilled in reverse engineering, where data cannot be provided, we can work backwards from a sample coil to provide a detailed coil specification and accurate fit.

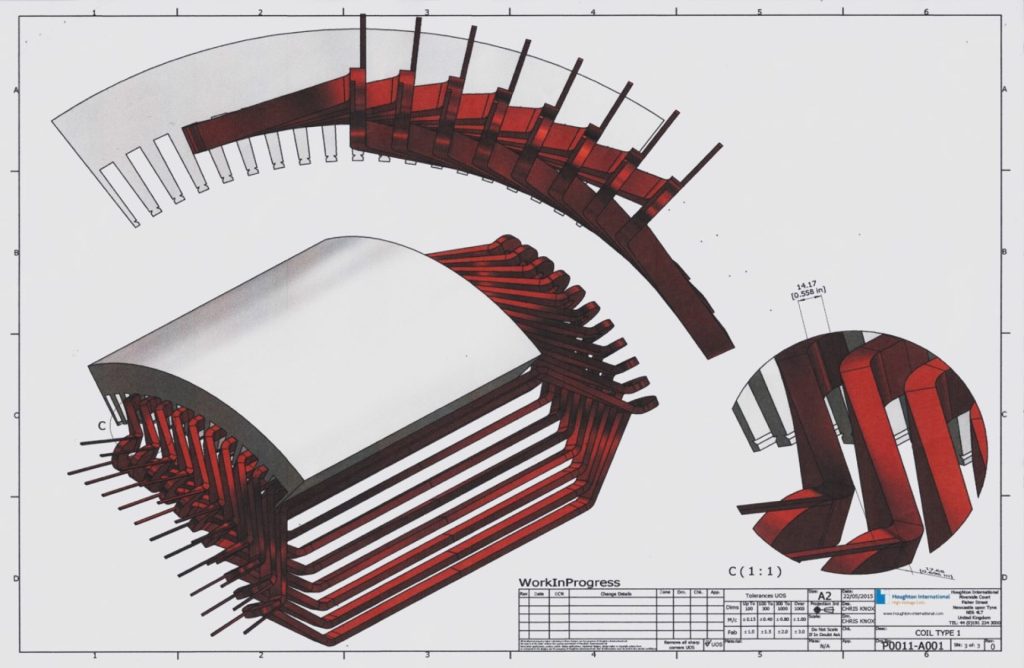

AutoCoil design software

Our bespoke AutoCoil design software utilises the latest technology to offer 3D coil design and slot build drawings for improved design and accurate fit. AutoCoil extrapolates data sheet information into 3D drawings which can be supplied alongside the quotation to illustrate the design and present a projection view of the cross section of the slot build. The 3D model supports the design process by allowing customers to visualise their coil requirements and improves the communication with the end user, supporting quote acceptance.

Worldwide in situ support services

In addition to supplying the coils we can also provide additional support to assist with carrying out the rewind. Our engineers routinely work both on site and at our customer’s premises either carrying out the full rewind or simply providing high voltage expertise to support the engineers carrying out the work.

We also provide in situ inspection, testing and fault diagnostics including air gap checks and partial discharge testing and other condition monitoring services to enable maintenance and rewinds to be planned in line with pre-arranged shut downs and reduce any unexpected downtime.

Related Case Studies

EMSL

Equipo de Pruebas

Contact us for more about our high voltage coil support services

Get in touch using the boxes below and we’ll get back to you.