Our in house, fully qualified welders have a range of experience providing welding support across the business.

TIG Welding

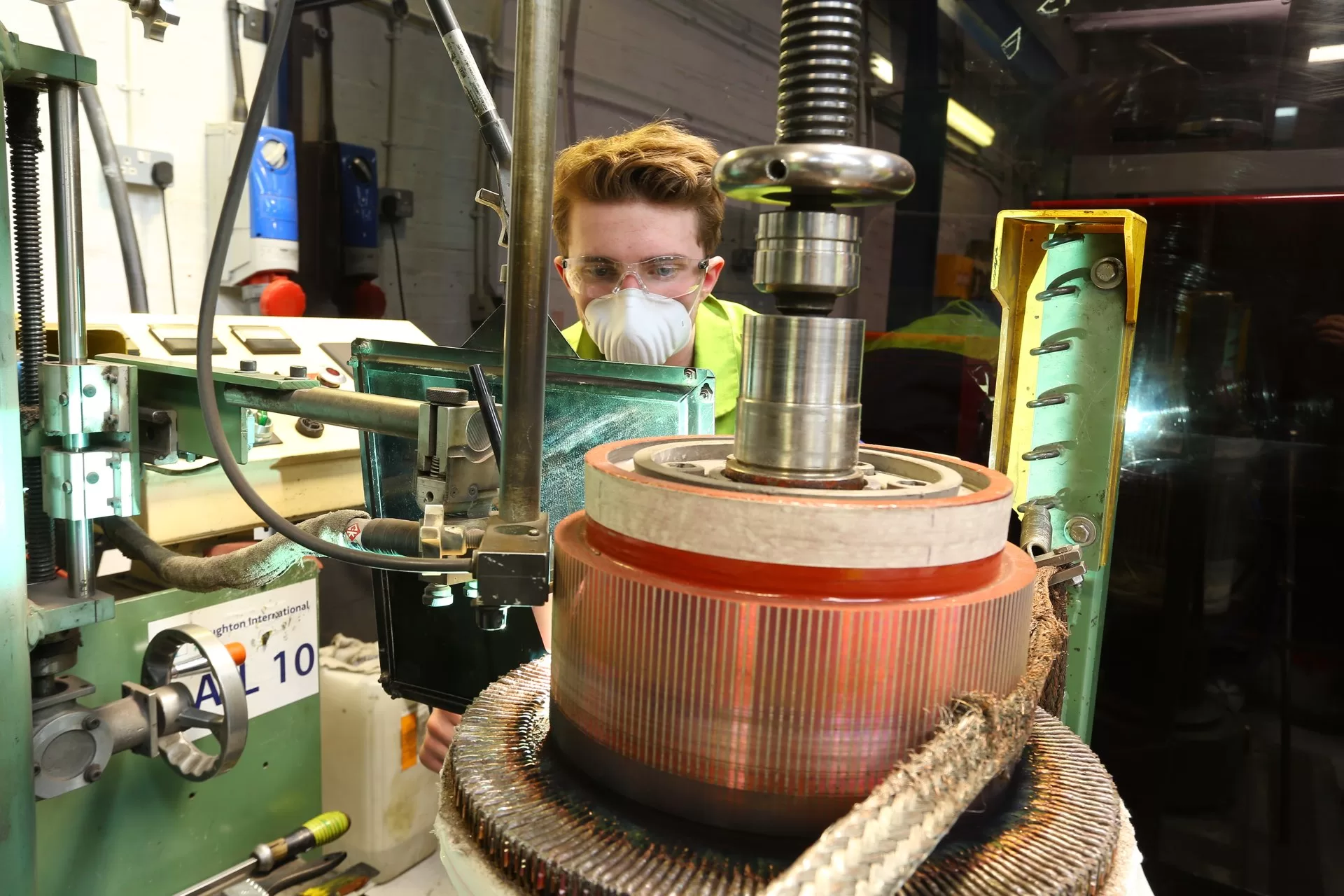

Houghton International has extensive experience in TIG welding services to meet the needs for light to medium steel manufacturing, fabrication projects and production welding. We specialise in TIG for armatures and commutators, with automated machines for smaller commutators and hand welding for larger jobs.

TIG (tungsten inert gas) is a process where high quality and precision is required. TIG can be used for carbon steel, stainless steel, aluminium and other alloys (ferrous and non-ferrous) and it is also referred to as GTAW (gas tungsten arc welding). Benefits of TIG welding services include:

- Stronger high-quality welds.

- Welds can be made with or without filler metal.

- Precise control of welding variables (heat).

- Free of spatter.

- Low distortion.

- Greater control over the weld than competing procedures, such as shielded metal arc welding and gas metal arc welding.

MIG Welding

We also offer MIG welding services for light to medium steel manufacturing, fabrication projects and production welding. MIG is a semi-automatic or automatic arc welding process preferred for its versatility and speed. It can be used for the following materials: carbon steel, stainless steel, aluminium, other alloys (ferrous and non-ferrous), and is also known as MAG (metal active gas) welding or GMAW (gas metal arc welding). Benefits of MIG welding services include:

- All position capability.

- Long welds can be made without starts and stops.

- Minimal post weld cleaning is required.

- Higher deposition rates than SMAW.

- Gain extra life out of product.

Stick Welding

A Stick welding service’s primary benefit is the versatility of the process and the simplicity of its equipment and operation. Stick is used predominantly to weld iron and steels (including stainless). However aluminium, nickel and copper alloys can also be welded using this method. Stick is more formally referred to as SMAW (shielded metal arc welding) or MMA (manual metal arc) welding. Benefits of Stick welding services include:

- Suited to windy, outdoor conditions.

- Forgiving on dirty or rusty metal.

- Can weld at a long distance from machine.

- Electrode provides and regulates its own flux.

- All position capability.

- Extremely versatile.

- Gain extra life out of product.

Contact us for more about our welding services

Get in touch using the boxes below and we’ll get back to you.