As the world continues to electrify energy efficiency is only increasing in importance. Electric motors account for two thirds of all the electrical energy used in industrial and commercial applications, with lifetime energy costs normally totalling many times the original cost of the motor.

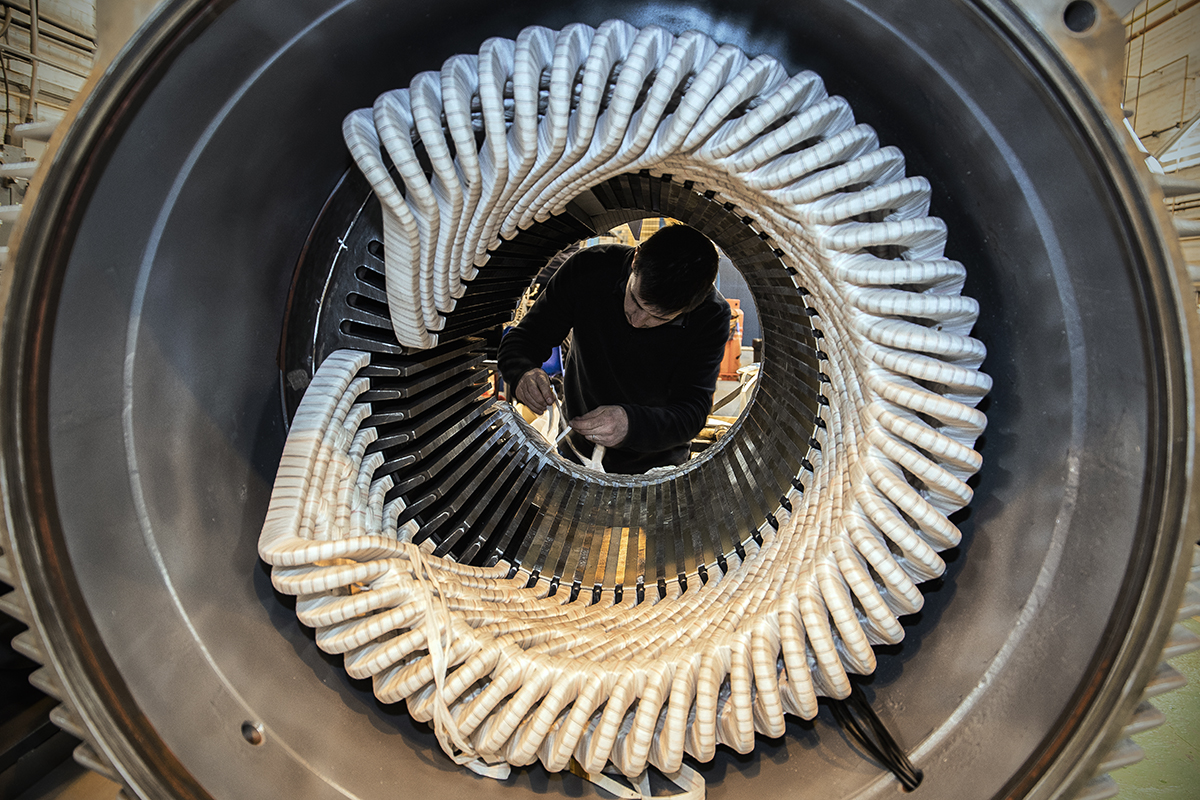

It is therefore important to ensure that motor efficiency is maximised as even a small percentage change in efficiency can have a greatly significant impact on overall running costs. That’s why at Houghton International we specialise in life extension and engineering improvements designed to deliver cost savings to our customers by increasing the reliability, efficiency and lifespan of assets.

It is well known that having motors rewound or repaired by a qualified service centre can result in significant savings over buying new. However, questions have long been raised about the effect of motor rewinds/repairs on efficiency, so in 2003 a joint study was published by EASA (Electrical Apparatus Service Authority) and the AEMT (Association of Electro Mechanical Trades). The comprehensive study, conducted using a third party testing laboratory, confirmed that motor efficiency could be maintained and sometimes even improved if the stator was rewound using established good practice procedures.

In recent years, with increased use of premium efficiency motors/IE3 motors around the world, questions were once again raised around whether the efficiency of these units could be maintained during the rewind process.

For the study ten new premium efficiency or IE3 motors, ranging from 30kW to 75kW, were performance tested pre- and post-rewind in accordance with IEEE Std. 112. The motors were rewound using good practice repair procedures as established in ANSI/EASA Std. AR100-2015 and the EASA/AEMT Good Practice Guide to Maintain Motor Efficiency – the standards that Houghton International also works to for all rewind and motor repair work.

The results showed changes in efficiency from -0.5% to +0.3%, with overall average efficiency change of -0.1%. Thus, individually and overall, there was no efficiency change to any motor other than that which would normally be expected due to fluctuations in the testing procedure.

This study continues to reaffirm that, so long as good practice procedures are adhered to, efficiency does not need to be compromised when repairing/rewinding a motor. To learn more about the study and its outcomes visit the EASA or AEMT websites.

This study further demonstrates the importance of choosing a qualified, accredited service centre in order to benefit from good practice procedures and access to industry expertise. As an EASA accredited service centre and member of the AEMT we are able to take advantage of international expertise and information exchange. Many of the projects we benefit not only from years of experience within the business, but also access to external knowledge and technical information via organisations such as EASA and the AEMT.

Houghton International’s engineers are experienced in complex projects where performance is improved or efficiency increased. It is clear that not only is it possible to maintain efficiency when rewinding, but changes can be made to improve machine performance. With reverse engineering capabilities and engineering consultancy available, our team can advise on all manner of queries, from minor repair work through to full project management. Contact us today or take a look at our case studies to learn more.