The challenge

Houghton International was awarded an order from SABIC, a Teesside based petrochemical manufacturing company, to overhaul a 250kW, 3.3kV 4-pole Ex N GEC motor used in their Olefins 6 plant, the second largest liquid naphtha cracker plant in Europe.

The solution

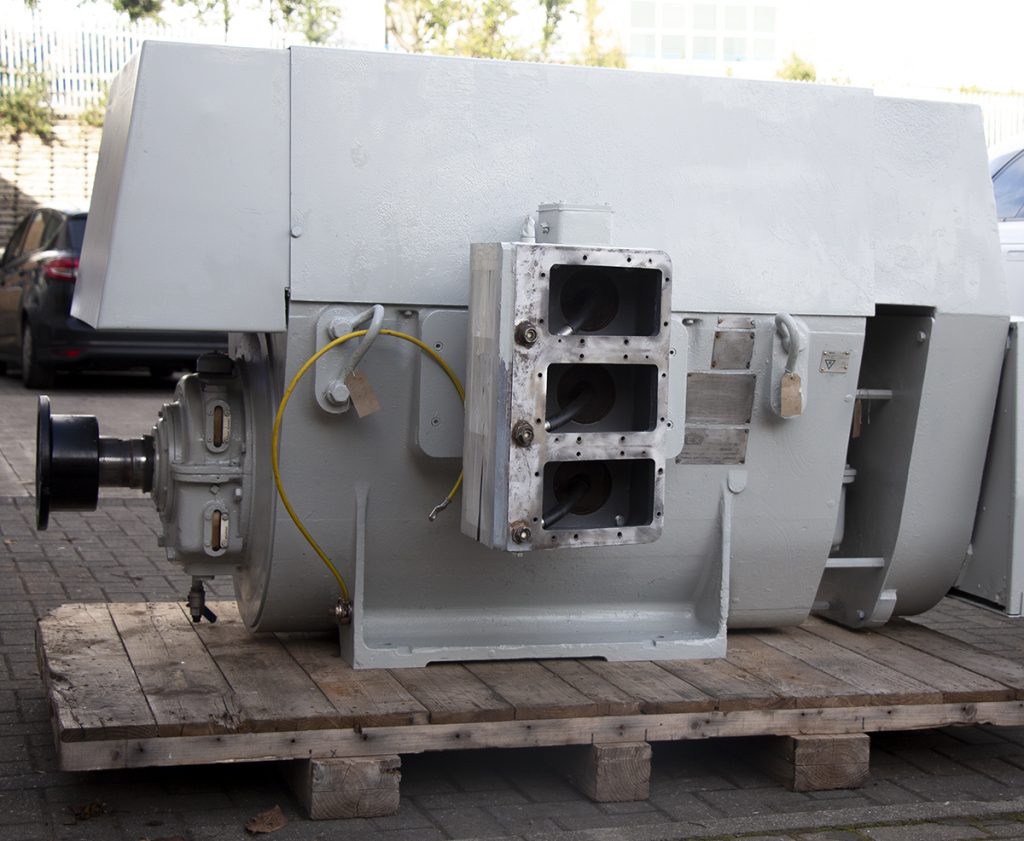

Initially, the customer requested an inspection and report on the condition of the motor. The motor was received from the customer in poor condition externally with substantial corrosion across the entire surface of the unit but upon dismantling, the internal component parts were found to be clean with little ingress evident in the windings. It was suspected that this was the first time that the motor was dismantled since the original installation other than routine bearing oil changes.

Based on these findings, Houghton International recommended a full in-depth overhaul of the motor at its IECEx certified facility by an experienced team of electro mechanical engineers. The overhaul consisted of stripping down and steam cleaning the motor, stoving the stator windings and dynamically balancing the rotor to ISO grade 2.5. Being a Ex motor, the mandatory hazardous area checks were also carried out with a full report produced at the end.

Remedial repairs to the covers were also carried out, and they were shot blasted and primed. A new sound baffle cover, cooling fan locking nut and new gaskets were manufactured to specification and the entire unit was then rebuilt.

Following the rebuild, the motor underwent full testing including a Baker test which ran a complete cycle of tests to ensure the integrity of all motor windings, an overall broad test run, and monitoring of vibration and all bearings before being returned to the customer’s site.

Why Houghton International

Related Services

The Results

To begin with, the customer thought that the existing motor was beyond economical repair because of the outside damage and a new motor would be required. However, after an inspection by Houghton International, the inside of the unit was found to be workable and an overhaul minimised the cost implications and disruption to the customer.

Furthermore, mid-way through the overhaul, the customer requested a much quicker turnaround. Renowned in the industry for a fast response, quick turnaround and responsive customer service, Houghton International was able to meet the demands of the customer and deliver the overhauled motor on time, ahead of the original schedule.

Houghton International assisted with the collection and strip down of an Ex N GEC motor as a top priority to support our business needs. Looking at the motor from the outset, we believed the motor was beyond repair, but an overhaul carried out by the team at Houghton International has extended its service life for the foreseeable future. Furthermore, in the middle of the overhaul, we requested a delivery date much earlier than first anticipated and Houghton International still delivered the motor on time. They went above and beyond in turning the motor around to reduce our business risk.

Michael Kast, Maintenance Planner, SABIC

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.