The challenge

A vertically mounted split case pump operating at Northumbrian Water’s Broken Scar Water Treatment Works was experiencing inefficiency, excess vibration and generally underperforming due to deterioration.

Northumbrian Water required a team to remove the pump and associated 3.3kV AEI induction motor from site and carry out an inspection, repair and overhaul on both assets before reinstallation.

Specialising in both pumps and motors, Houghton International had the capability to repair both the pump and motor and the connecting prop shaft, ensuring the whole system would perform optimally when recommissioned.

The solution

Initial inspections on the pump at the water treatment works identified that the seals on the pump had failed causing a severe leak. Houghton International’s site services team removed the pump and motor and arranged for the transportation back to its fully equipped workshop in Newcastle upon Tyne.

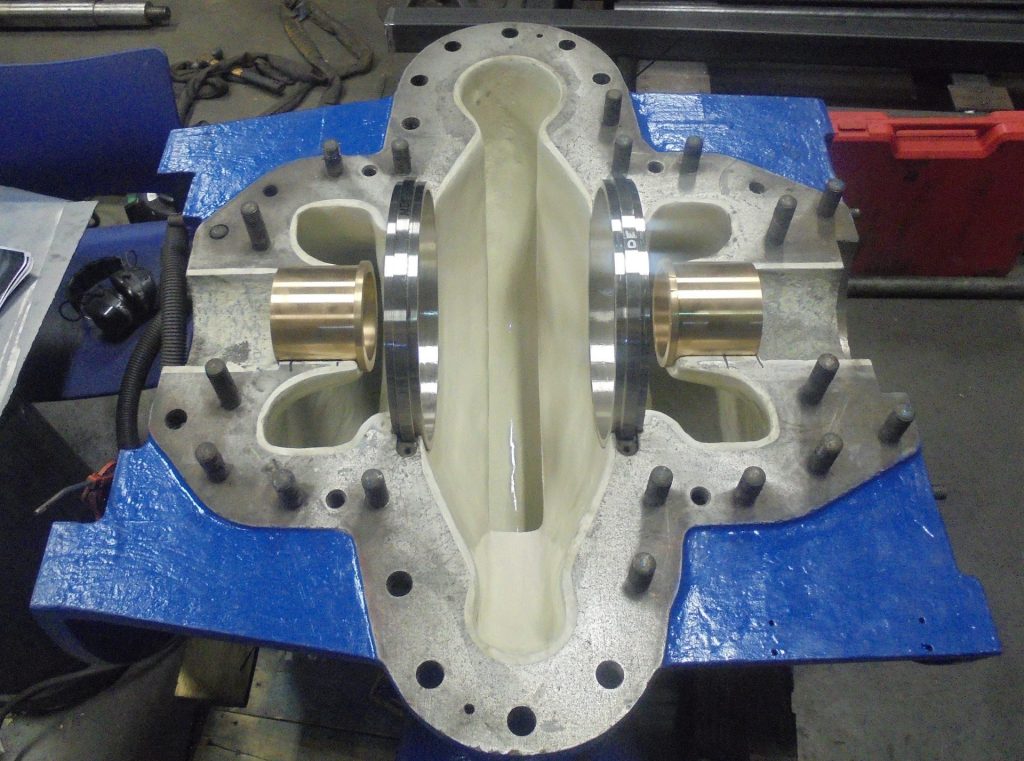

Once back at the workshop, the pump was stripped down and cleaned with a full inspection carried out to find out what other issues had caused the pump to perform inefficiently. The neck bushes were found to be seized onto the shaft sleeves which was the reason for the high vibration.

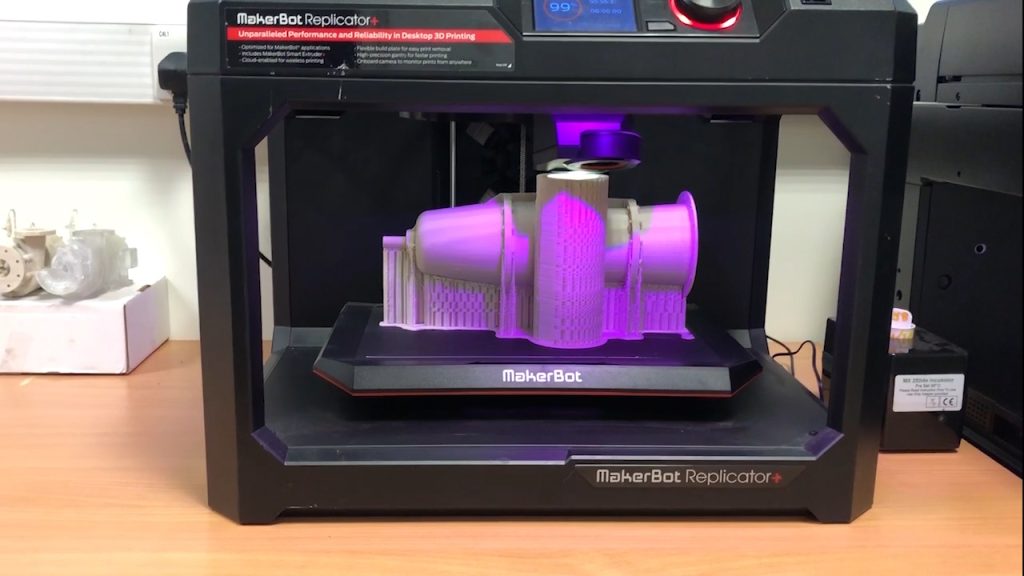

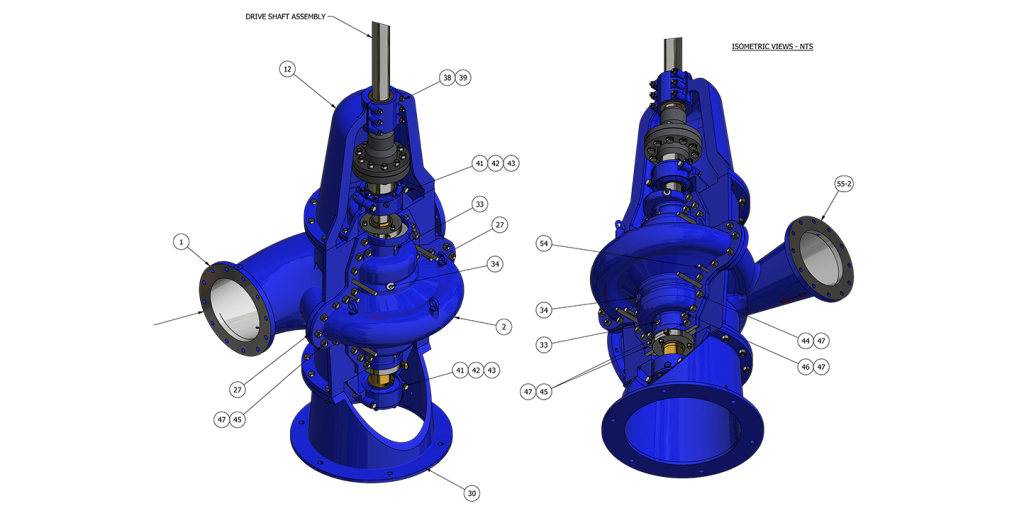

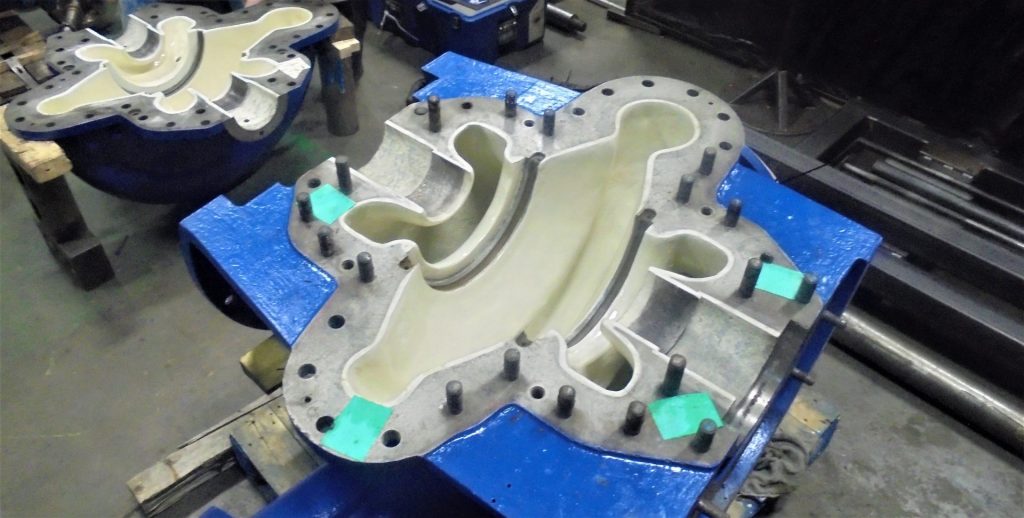

To begin with, weld repairs were carried out to the damaged vanes and the impeller runners were skimmed and sleeved bringing them back to new and balanced to G2.5. The full pump was then laser scanned and using our 3D CAD software, drawings were created, and parts were manufactured in house as a more cost-effective solution than purchasing from OEM. Parts of the pump such as the impeller rings were manufactured and replaced to bring clearances back into tolerance as were neck bushes and shaft sleeves. New bearings were also fitted.

A specialist friction-reducing protective coating was then applied to the pump to further improve efficiency by 3-5%. The pump seal faces were upgraded from old materials to modern mechanical seal faces to increase reliability.

In addition, the associated motor also underwent an inspection with a standard overhaul being carried out including cleaning, balancing, testing with the bearings and seals fully replaced.

Once the pump and motor overhaul were complete, they underwent a program of comprehensive testing with the pump being tested at Houghton International’s pump test facility before being returned to site and reinstalled by the site services team.

Why Houghton International

Related Services

The Results

Having one supplier to repair both pumps and motors provided many benefits including increased quality assurance and the ability to fully test the whole system. Furthermore, having a site services team allowed Houghton International to fully manage the project from removing the assets from site, repairing them in house and then reinstalling them at the Broken Scar Water Treatment Works, all on one order with one point of contact.

With reverse engineering capabilities in-house, a number of parts that were damaged or worn beyond repair were easily replaced. This also provided the opportunity to make modifications to the parts to bring the old pump up to modern standards. All these works, including the application of the specialist coating, allowed the pump to perform at its Best Efficiency Point (BEP).

Once again, Houghton International provided an exceptional level of service and kept us informed of progress throughout the project. The modifications and works carried out on the pump and subsequent motor will allow them to run more efficiently and economically whilst lengthening their working lifespan which is exactly what we wanted to achieve.

Alex Wallis, Maintenance Electrician, Northumbrian Water

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.