The challenge

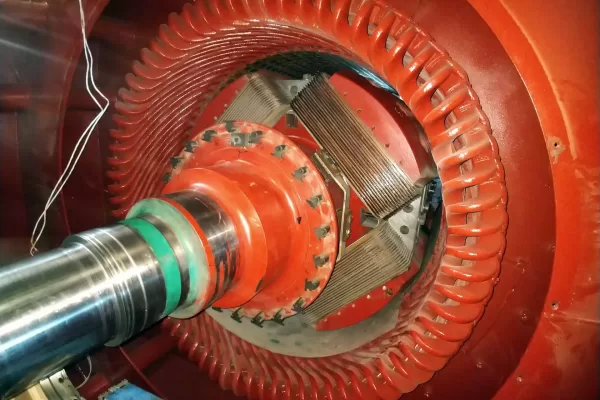

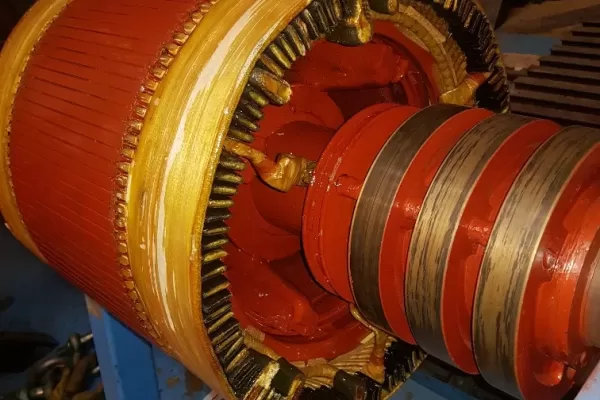

Houghton International was awarded an order from Armature Electric to manufacture 48 (+2 spare) high voltage stator coils with a transposition twist for a 13.8 kV, 14,000HP GE refiner duty motor.

The solution

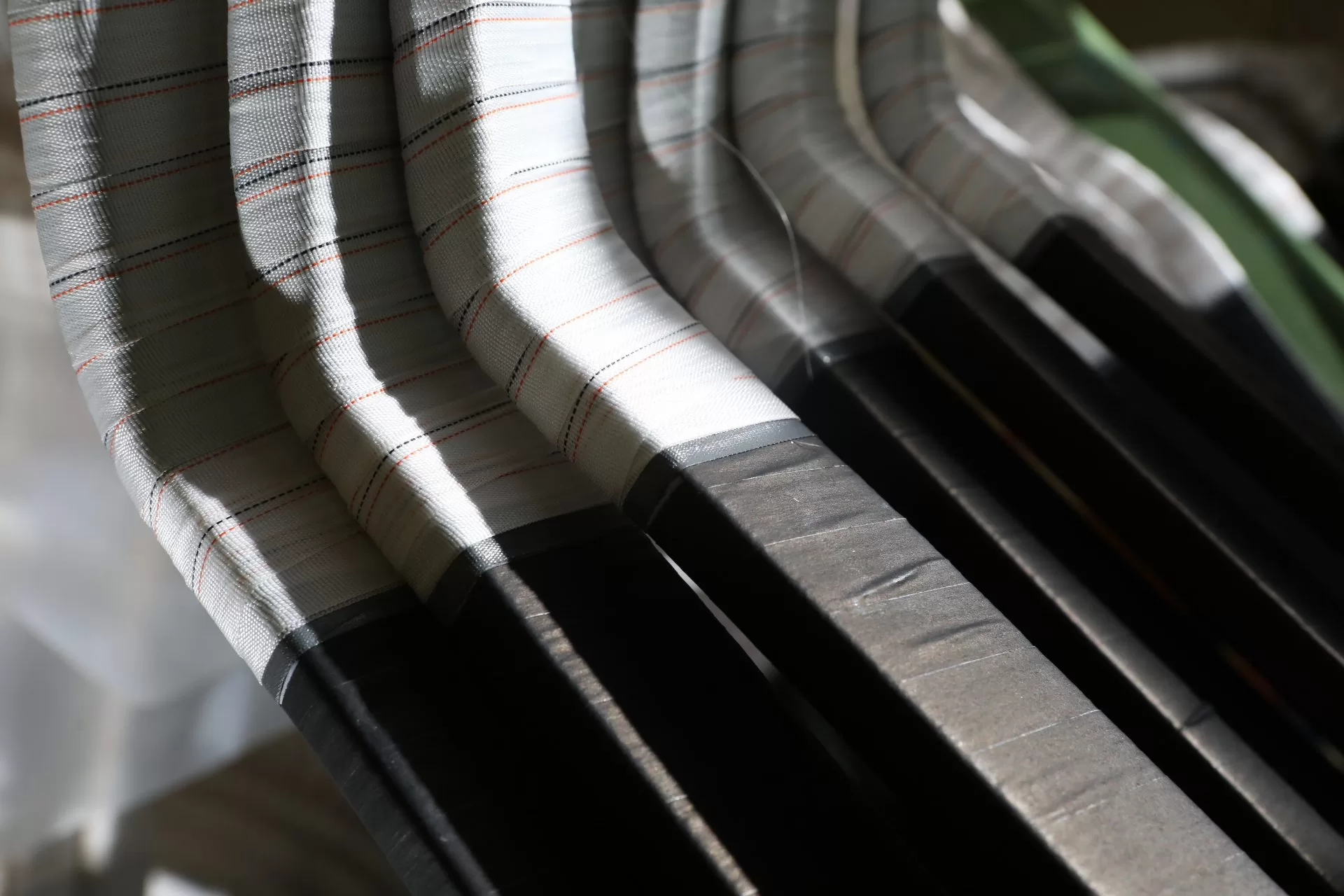

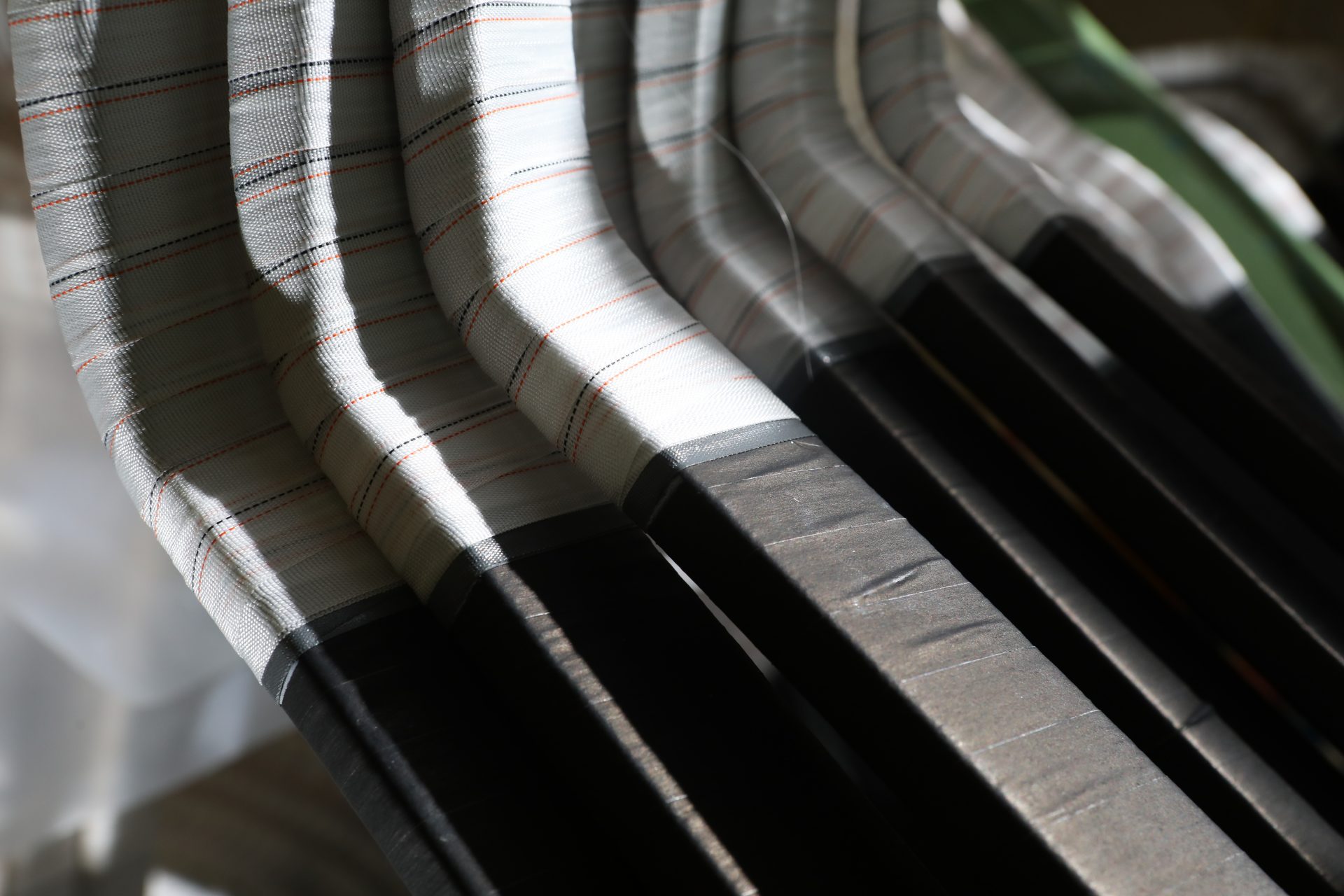

At its dedicated coil manufacturing facility, Houghton International manufactured and supplied all coils utilising its unique HiFLEX insulation system.

As per the specification, the coils were manufactured to tight tolerances giving a consistent fit which in turn helps to reduce partial discharge (PD) levels. With higher voltage machines, PD is a critical factor in the life expectancy of the motor. The quality and fit of coils can significantly impact PD readings so therefore Houghton International work to tight tolerances to give best results.

Why Houghton International

Related Services

The Results

The HiFLEX fully cured and fully flexible insulation system gives improved fit, easier install and reduces the risk of damage to the coils during installation.

Prior to dispatch, all coils were quality assurance checked and supplied with an auxiliary winding kit to ensure that the completion of the rewind process can be carried out easily and safely by the customer. All coils were delivered to Armature Electric in a foil vacuum sealed bag system inside a moisture proof wooden crate to ensure excellent protection throughout transit.

Over the past couple of years, we have been utilizing the Houghton HIFLEX High Voltage coil design. The feedback that I have received from our winding teams is rather positive. They are very impressed with the precision of the coil geometry and the overall high quality of the coil build and finish.

The final PD testing of the last Large HV Motor, (a 14,000HP GE refiner duty motor), produced the best test results we have ever seen. This is a true testament to the high-quality standards built into the HIFLEX coil design.

The entire team at Houghton is a pleasure to deal with, they are very professional, extremely responsive, highly knowledgeable and always willing to take the time to work through any technical issues that arise.

In our market, customers demand the highest quality product for their critical assets, we can honestly say that we can exceed their expectations both with the quality of product and delivery responsiveness.

We will continue to promote the Houghton coil systems to our customers, and we look forward to continuing our relationship with Houghton International.

Joe Higgs, General Manager, Armature Electric

Related Case Studies

Want to know more about our past projects?

Get in touch using the boxes below and we’ll get back to you.